V10 Vane Pumps

Category:

V10/V20 series vane pumps

Summary:

Keywords:

Description

Specifications

|

Model |

Displacement |

Geometric |

Antiwear oil or |

Water glycol fluid |

Water-in-oil emulsions |

|||

|

Max. pressure |

Max. speed |

Max. pressure |

Max. speed |

Max. pressure |

Max. speed |

|||

|

V10 |

1 |

3.3 |

17.2 |

4800 |

12.4 |

1800 |

10.3 |

1800 |

|

2 |

6.6 |

4500 |

||||||

|

3 |

9.8 |

4000 |

||||||

|

4 |

13.1 |

3400 |

||||||

|

5 |

16.4 |

3200 |

||||||

|

6 |

19.5 |

15.2 |

3000 |

10.9 |

||||

|

7 |

22.8 |

13.8 |

2800 |

|||||

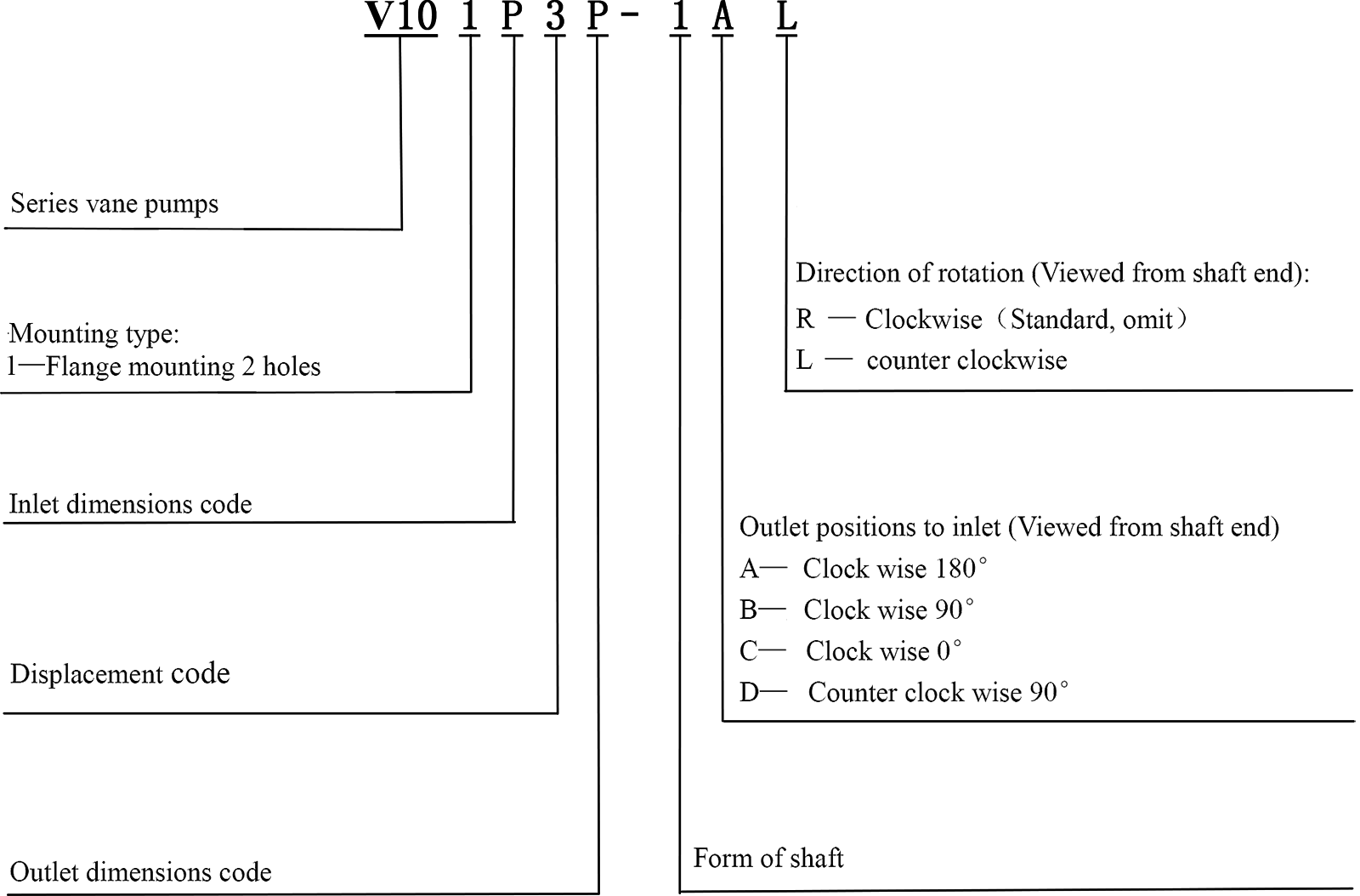

Model Code

Installation and Use

1. In installation, the tolerance of concentricity between shaft of pump and motor must be less than 0.10mm(TIR) and the maximum permissible angle error is less than 0.2 degrees by using the flexible coupling; The pump shaft shall not bear the radial and axial load ; The carrier must be firm with good rigidity and can fully absorb vibrations.

2. Set the suction pressure at pump inlet port : Recommended inlet pressure is 0 to 35Kpa.

3. Oil should be kept clean, pipes and tanks must be thoroughly cleaned; The cleanness level of oil should be within NSA12.

4. Nomal pump operation(at rated conditions)is based on the use of SAE10W oil in the 38 ℃ to 82℃ range (or comparable viscosities)

5. Check the inlet, outlet and direction of rotation before starting the pump. Turn the shaft of pump evenly and nimbly by hand after fixing the pump. At the time of first-starting ,if the pump does not immediately prime , air should be bled from the pump delivery line .

6. When first put into use, the pump body and oil suction pipeline should be filled with oil, and the pump shall not be allowed to operate without oil.

7. Do not start the pump when the outlet pressure is lower than the inlet pressure. This will cause work noise and blade instability.

8. Cold start condition:When operating SAE10W oil in the 860 to 40 cSt range, the speed and pressure should be limited to 50% or less of their respective rated values until the system has warmed up. Extreme caution must be used when starting units when fluid viscosity are greater than 860 cSt, Care should be exercised to warm up the entire system, including remote cylinders and motors.

9. At high temperature, viscosities must not be less than 13cSt, Temperatures should not exceed 99 ℃ because the expectancy of cartridge kite and elastomers will decrease

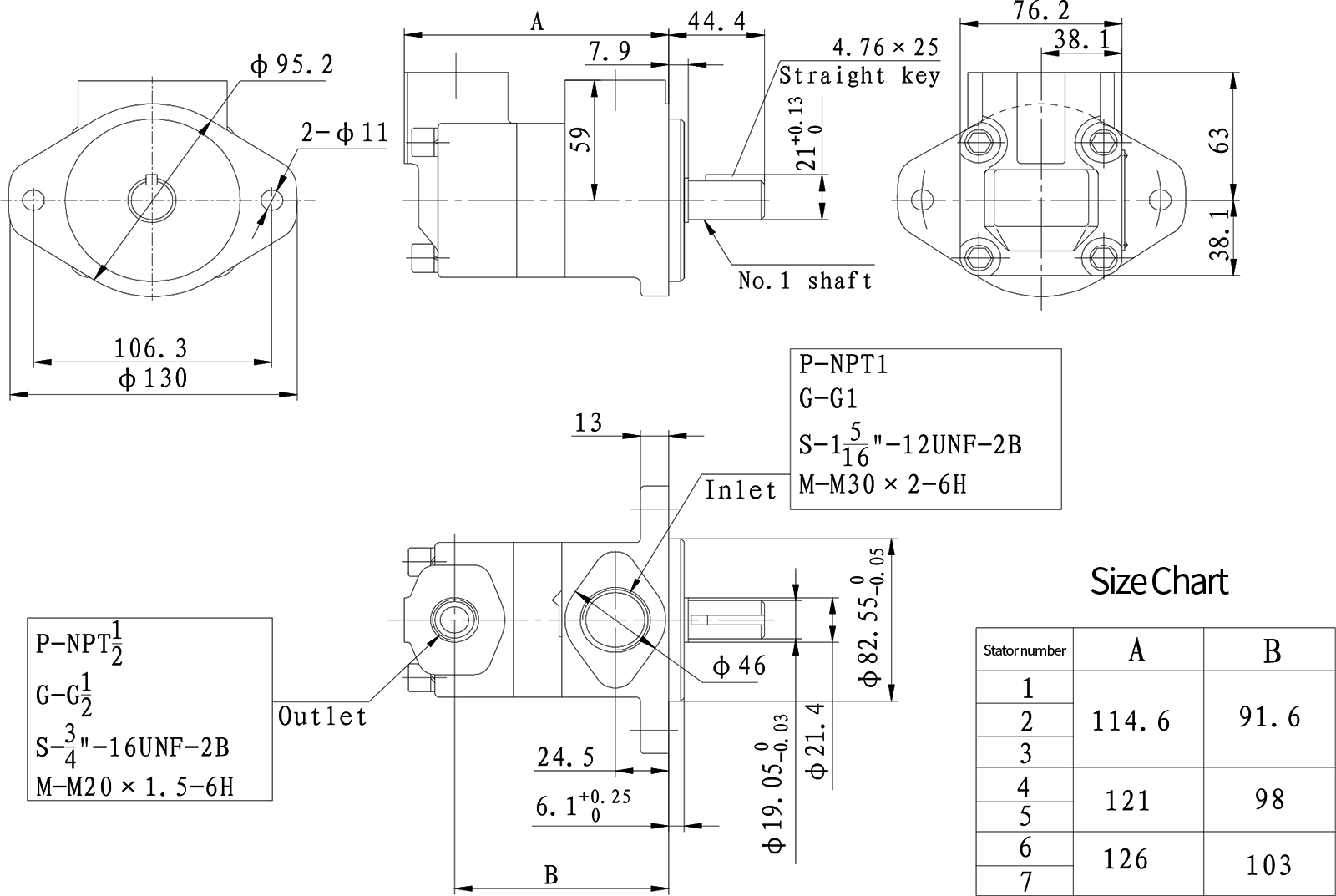

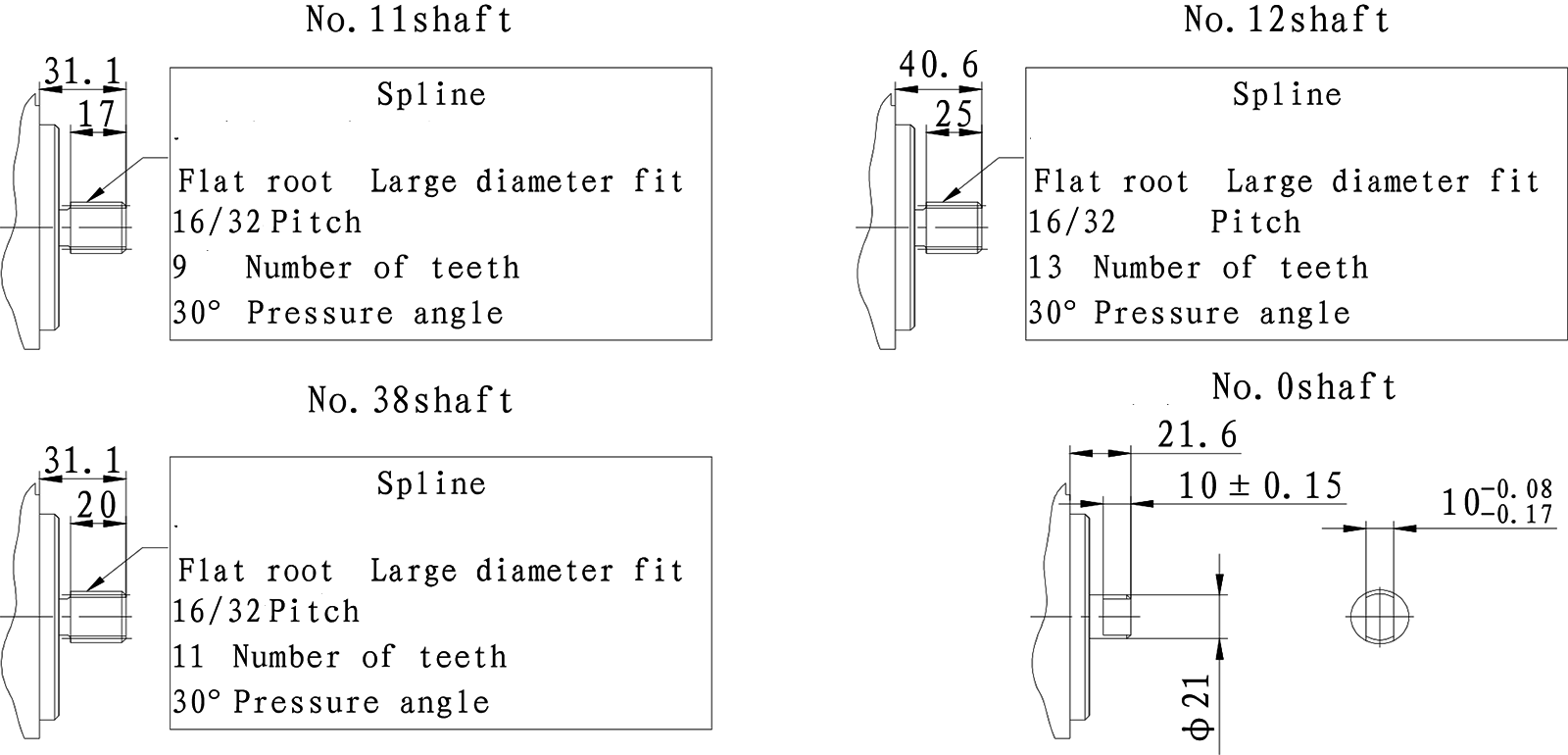

Install Connection Dimensions

Previous

Next

Previous

V20 Vane Pumps

Next