APPLICATIONS

Baler 3

Baler 2

Extruder

Extruder 2

Extruder 3

Hydraulic press 4

Hydraulic press 3

PRODUCT

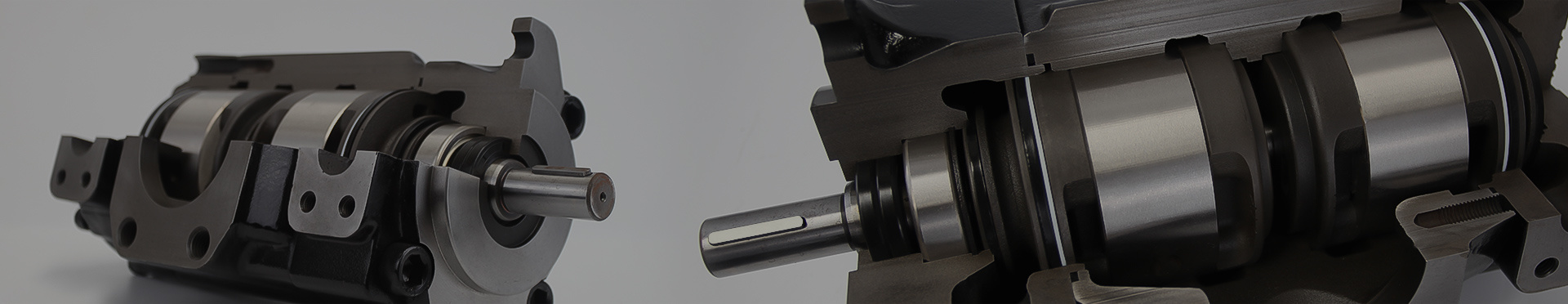

This product use float side panel, vane of dowel pin structure, technics of double-edged vane and wholly new low noise technology cure to process stator. Compared with other dosing vane pumps, its advantages are: ● High working pressure – it can reduce the size of hydraulic actuator ,control valves and tubing,which makes for cutting the cost, you can also extend its working life by lowering the working pressure. ● High efficiency – both volumetric and mechanical efficiency are higher than 94%,so it helps to raise productivity, reduce heating and running cost. ● Smaller pressure fluctuation – it will reduce the noise of tubing and extend operating life of other hydraulic element. ● High fouling resistance –using vane of double lips structure provides high fouling resistance and long operation life ● Low noise – the vane structure of dowel pin which can decrease the force on the stator which comes from vane efficiently. We also adopt wholly new low noise technology stator, so it produces little noise. And the T*L series pumps with thicker body make for reducing mechanical amp litude and lower noise. ● Wide speed range – combining pumps core which has large displacement with smaller pumps body to produce large displacement pumps with low noise. In particular, this series of products is suitable for cutting machinery plastic machinery, leather machinery, pressing machinery, engineering machinery, metallurgical machinery and so on.

This product use float side panel, vane of dowel pin structure, technics of double-edged vane and wholly new low noise technology cure to process stator. Compared with other dosing vane pumps, its advantages are: ● High working pressure – it can reduce the size of hydraulic actuator ,control valves and tubing,which makes for cutting the cost, you can also extend its working life by lowering the working pressure. ● High efficiency – both volumetric and mechanical efficiency are higher than 94%,so it helps to raise productivity, reduce heating and running cost. ● Smaller pressure fluctuation – it will reduce the noise of tubing and extend operating life of other hydraulic element. ● High fouling resistance –using vane of double lips structure provides high fouling resistance and long operation life ● Low noise – the vane structure of dowel pin which can decrease the force on the stator which comes from vane efficiently. We also adopt wholly new low noise technology stator, so it produces little noise. And the T*L series pumps with thicker body make for reducing mechanical amp litude and lower noise. ● Wide speed range – combining pumps core which has large displacement with smaller pumps body to produce large displacement pumps with low noise. In particular, this series of products is suitable for cutting machinery plastic machinery, leather machinery, pressing machinery, engineering machinery, metallurgical machinery and so on.

This product use float side panel, vane of dowel pin structure, technics of double-edged vane and wholly new low noise technology cure to process stator. Compared with other dosing vane pumps, its advantages are: ● High working pressure – it can reduce the size of hydraulic actuator ,control valves and tubing,which makes for cutting the cost, you can also extend its working life by lowering the working pressure. ● High efficiency – both volumetric and mechanical efficiency are higher than 94%,so it helps to raise productivity, reduce heating and running cost. ● Smaller pressure fluctuation – it will reduce the noise of tubing and extend operating life of other hydraulic element. ● High fouling resistance –using vane of double lips structure provides high fouling resistance and long operation life ● Low noise – the vane structure of dowel pin which can decrease the force on the stator which comes from vane efficiently. We also adopt wholly new low noise technology stator, so it produces little noise. And the T*L series pumps with thicker body make for reducing mechanical amp litude and lower noise. ● Wide speed range – combining pumps core which has large displacement with smaller pumps body to produce large displacement pumps with low noise. In particular, this series of products is suitable for cutting machinery plastic machinery, leather machinery, pressing machinery, engineering machinery, metallurgical machinery and so on.

This product use float side panel, vane of dowel pin structure, technics of double-edged vane and wholly new low noise technology cure to process stator. Compared with other dosing vane pumps, its advantages are: ● High working pressure – it can reduce the size of hydraulic actuator ,control valves and tubing,which makes for cutting the cost, you can also extend its working life by lowering the working pressure. ● High efficiency – both volumetric and mechanical efficiency are higher than 94%,so it helps to raise productivity, reduce heating and running cost. ● Smaller pressure fluctuation – it will reduce the noise of tubing and extend operating life of other hydraulic element. ● High fouling resistance –using vane of double lips structure provides high fouling resistance and long operation life ● Low noise – the vane structure of dowel pin which can decrease the force on the stator which comes from vane efficiently. We also adopt wholly new low noise technology stator, so it produces little noise. And the T*L series pumps with thicker body make for reducing mechanical amp litude and lower noise. ● Wide speed range – combining pumps core which has large displacement with smaller pumps body to produce large displacement pumps with low noise. In particular, this series of products is suitable for cutting machinery plastic machinery, leather machinery, pressing machinery, engineering machinery, metallurgical machinery and so on.

This product use float side panel, vane of dowel pin structure, technics of double-edged vane and wholly new low noise technology cure to process stator. Compared with other dosing vane pumps, its advantages are: ● High working pressure – it can reduce the size of hydraulic actuator ,control valves and tubing,which makes for cutting the cost, you can also extend its working life by lowering the working pressure. ● High efficiency – both volumetric and mechanical efficiency are higher than 94%,so it helps to raise productivity, reduce heating and running cost. ● Smaller pressure fluctuation – it will reduce the noise of tubing and extend operating life of other hydraulic element. ● High fouling resistance –using vane of double lips structure provides high fouling resistance and long operation life ● Low noise – the vane structure of dowel pin which can decrease the force on the stator which comes from vane efficiently. We also adopt wholly new low noise technology stator, so it produces little noise. And the T*L series pumps with thicker body make for reducing mechanical amp litude and lower noise. ● Wide speed range – combining pumps core which has large displacement with smaller pumps body to produce large displacement pumps with low noise. In particular, this series of products is suitable for cutting machinery plastic machinery, leather machinery, pressing machinery, engineering machinery, metallurgical machinery and so on.

This product use float side panel, vane of dowel pin structure, technics of double-edged vane and wholly new low noise technology cure to process stator. Compared with other dosing vane pumps, its advantages are: ● High working pressure – it can reduce the size of hydraulic actuator ,control valves and tubing,which makes for cutting the cost, you can also extend its working life by lowering the working pressure. ● High efficiency – both volumetric and mechanical efficiency are higher than 94%,so it helps to raise productivity, reduce heating and running cost. ● Smaller pressure fluctuation – it will reduce the noise of tubing and extend operating life of other hydraulic element. ● High fouling resistance –using vane of double lips structure provides high fouling resistance and long operation life ● Low noise – the vane structure of dowel pin which can decrease the force on the stator which comes from vane efficiently. We also adopt wholly new low noise technology stator, so it produces little noise. And the T*L series pumps with thicker body make for reducing mechanical amp litude and lower noise. ● Wide speed range – combining pumps core which has large displacement with smaller pumps body to produce large displacement pumps with low noise. In particular, this series of products is suitable for cutting machinery plastic machinery, leather machinery, pressing machinery, engineering machinery, metallurgical machinery and so on.

This product use float side panel, vane of dowel pin structure, technics of double-edged vane and wholly new low noise technology cure to process stator. Compared with other dosing vane pumps, its advantages are: ● High working pressure – it can reduce the size of hydraulic actuator ,control valves and tubing,which makes for cutting the cost, you can also extend its working life by lowering the working pressure. ● High efficiency – both volumetric and mechanical efficiency are higher than 94%,so it helps to raise productivity, reduce heating and running cost. ● Smaller pressure fluctuation – it will reduce the noise of tubing and extend operating life of other hydraulic element. ● High fouling resistance –using vane of double lips structure provides high fouling resistance and long operation life ● Low noise – the vane structure of dowel pin which can decrease the force on the stator which comes from vane efficiently. We also adopt wholly new low noise technology stator, so it produces little noise. And the T*L series pumps with thicker body make for reducing mechanical amp litude and lower noise. ● Wide speed range – combining pumps core which has large displacement with smaller pumps body to produce large displacement pumps with low noise. In particular, this series of products is suitable for cutting machinery plastic machinery, leather machinery, pressing machinery, engineering machinery, metallurgical machinery and so on.

This product use float side panel, vane of dowel pin structure, technics of double-edged vane and wholly new low noise technology cure to process stator. Compared with other dosing vane pumps, its advantages are: ● High working pressure – it can reduce the size of hydraulic actuator ,control valves and tubing,which makes for cutting the cost, you can also extend its working life by lowering the working pressure. ● High efficiency – both volumetric and mechanical efficiency are higher than 94%,so it helps to raise productivity, reduce heating and running cost. ● Smaller pressure fluctuation – it will reduce the noise of tubing and extend operating life of other hydraulic element. ● High fouling resistance –using vane of double lips structure provides high fouling resistance and long operation life ● Low noise – the vane structure of dowel pin which can decrease the force on the stator which comes from vane efficiently. We also adopt wholly new low noise technology stator, so it produces little noise. And the T*L series pumps with thicker body make for reducing mechanical amp litude and lower noise. ● Wide speed range – combining pumps core which has large displacement with smaller pumps body to produce large displacement pumps with low noise. In particular, this series of products is suitable for cutting machinery plastic machinery, leather machinery, pressing machinery, engineering machinery, metallurgical machinery and so on.

This product use float side panel, vane of dowel pin structure, technics of double-edged vane and wholly new low noise technology cure to process stator. Compared with other dosing vane pumps, its advantages are: ● High working pressure – it can reduce the size of hydraulic actuator ,control valves and tubing,which makes for cutting the cost, you can also extend its working life by lowering the working pressure. ● High efficiency – both volumetric and mechanical efficiency are higher than 94%,so it helps to raise productivity, reduce heating and running cost. ● Smaller pressure fluctuation – it will reduce the noise of tubing and extend operating life of other hydraulic element. ● High fouling resistance –using vane of double lips structure provides high fouling resistance and long operation life ● Low noise – the vane structure of dowel pin which can decrease the force on the stator which comes from vane efficiently. We also adopt wholly new low noise technology stator, so it produces little noise. And the T*L series pumps with thicker body make for reducing mechanical amp litude and lower noise. ● Wide speed range – combining pumps core which has large displacement with smaller pumps body to produce large displacement pumps with low noise. In particular, this series of products is suitable for cutting machinery plastic machinery, leather machinery, pressing machinery, engineering machinery, metallurgical machinery and so on.