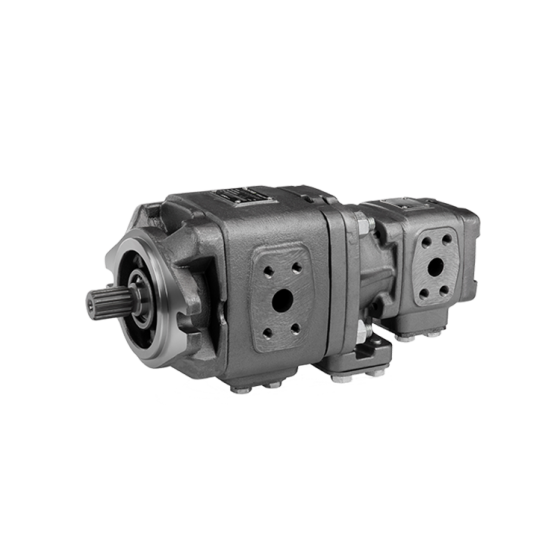

T6C/T6CL High-Pressure Pin-Type Vane Pump

Key words:

T6/VANE PUMP/HYDRAULIC PUMP

Thanks to the adoption of floating side plates, a pin-type vane structure, dual-edge vane technology, and a brand-new low-noise stator profile, this product series boasts the following superior features compared to other types of fixed-displacement vane pumps:

● High working pressure—can reduce the size of hydraulic actuators, hydraulic control valves, and piping, thereby lowering installation costs; if operated at reduced pressure, it can extend the service life.

● High efficiency—Typical values for volumetric efficiency and mechanical efficiency exceed 94%, which helps boost productivity, reduce heat generation, and lower operating costs of hydraulic equipment. It also allows rotational speeds as low as 600 r/min even under full-pressure operating conditions.

● Low pressure pulsation—this reduces noise in hydraulic pipelines and extends the service life of other components in the hydraulic circuit;

● Strong anti-pollution capability—Thanks to the blade’s double-lip design, it boasts exceptional resistance to contamination and a long service life.

● Low Noise — Thanks to the use of a pin-type blade structure, the force exerted by the blades on the stator is significantly reduced. Additionally, a brand-new low-noise stator profile has been adopted, resulting in extremely low noise levels. In particular, the T*L series oil pumps feature a pump body with a thicker casting design, which further reduces the amplitude of mechanical vibrations and lowers noise even more.

● Wide speed range—By combining a high-displacement pump core, it’s possible to assemble low-noise pumps with larger displacement using smaller-sized housings. This product series is particularly well-suited for hydraulic systems in high-performance equipment such as cutting machinery, plastic machinery, leather machinery, press machinery, construction machinery, and metallurgical machinery.

● High working pressure—can reduce the size of hydraulic actuators, hydraulic control valves, and piping, thereby lowering installation costs; if operated at reduced pressure, it can extend the service life.

● High efficiency—Typical values for volumetric efficiency and mechanical efficiency exceed 94%, which helps boost productivity, reduce heat generation, and lower operating costs of hydraulic equipment. It also allows rotational speeds as low as 600 r/min even under full-pressure operating conditions.

● Low pressure pulsation—this reduces noise in hydraulic pipelines and extends the service life of other components in the hydraulic circuit;

● Strong anti-pollution capability—Thanks to the blade’s double-lip design, it boasts exceptional resistance to contamination and a long service life.

● Low Noise — Thanks to the use of a pin-type blade structure, the force exerted by the blades on the stator is significantly reduced. Additionally, a brand-new low-noise stator profile has been adopted, resulting in extremely low noise levels. In particular, the T*L series oil pumps feature a pump body with a thicker casting design, which further reduces the amplitude of mechanical vibrations and lowers noise even more.

● Wide speed range—By combining a high-displacement pump core, it’s possible to assemble low-noise pumps with larger displacement using smaller-sized housings. This product series is particularly well-suited for hydraulic systems in high-performance equipment such as cutting machinery, plastic machinery, leather machinery, press machinery, construction machinery, and metallurgical machinery.

Details

Technical Specifications

Specification Series

| Pump core specifications

| Theoretical displacement q i | Minimum rotational speed | Maximum rotational speed | Maximum pressure | ||||||

| HF-0 HF-1 HF-2 | HF-3 HF-4 HF-5 | HF-0, HF-2 | HF-1, HF-4, HF-5 | HF-3 | |||||||

| Intermittent | Continuous | Intermittent | Continuous | Intermittent | Continuous | ||||||

| mL/r | r/min | r/min | r/min | bar | bar | bar | bar | bar | bar | ||

T6C T6CL | 003 | 10.8 | 600

| 2800

| 1800

| 275 | 240 | 210 | 175 | 175 | 140 |

| 005 | 17.0 | ||||||||||

| 006 | 21.2 | ||||||||||

| 008 | 26.2 | ||||||||||

| 010 | 34.0 | ||||||||||

| 012 | 37.0 | ||||||||||

| 014 | 46.0 | ||||||||||

| 017 | 58.0 | ||||||||||

| 020 | 63.5 | ||||||||||

| 022 | 70.0 | ||||||||||

| 025 | 79.0 | 2500 | |||||||||

| 028 | 89.0 | 210 | 160 | 160 | |||||||

| 031 | 100.0 | ||||||||||

Note: HF-0, HF-2 = Petroleum-based anti-wear hydraulic oils;

HF-1 = Petroleum-based hydraulic oil (non-wear-resistant);

HF-3 = Oil-in-Water Emulsion;

HF-4 = Water-glycol;

HF-5 = Synthetic hydraulic oil (such as phosphate ester fluid).

Model Description

Installation and Use

Initial startup inspection: Verify the correctness of the hydraulic station’s design and assembly.

● In the fuel tank, the distance between the oil suction pipe and the oil return pipe should be kept as large as possible.

● Both the oil suction port and the oil return port shall be designed with beveled edges to increase the flow cross-section and reduce the flow velocity. It is recommended that the bevel angle of the cross-section be no less than 45°. The flow velocity at the oil suction port should be in the range of 0.5 < v < 1.9 m/s, while the flow velocity at the oil return port should be v < 6 m/s.

● The oil intake port and the return oil port shall always be kept submerged below the oil level in the tank, especially under the most adverse conditions (e.g., when all hydraulic cylinders in the system are fully extended to their outermost positions); this condition must be strictly maintained.

● The air filter’s specifications should be more than three times the system’s maximum instantaneous return oil flow rate (e.g., when the system is operating with all hydraulic cylinders retracting).

● The oil return line should be equipped with an air vent valve for air release:

Another method for bleeding air is to slightly loosen the pump’s outlet connection, allowing a small amount of leakage. Once no more air bubbles appear in the leaking oil, tighten the loosened section again. Note: When using this method, it must be performed under low-pressure conditions, and ensure that the pressure does not rise.

Initial startup:

● Check whether the pump’s rotation direction is correct;

● The hydraulic pump should be properly filled with oil and thoroughly bled of air;

● Briefly jog the hydraulic pump for several seconds. If the pump’s outlet is equipped with a relief valve, loosen it slightly to reduce the pressure to the minimum level. If the pump generates excessive noise during operation, troubleshoot the system.

● Do not operate the pump at high speed or high pressure before performing a complete initial startup inspection.

Application Instructions

Drive shaft and coupling—coupling with splined bore

● The spline holes of the coupling should be capable of floating and automatically aligning. If both halves of the coupling are rigidly connected, the misalignment between them should be less than ±0.15/25.4 mm (the total reading difference of a dial indicator) to minimize wear. Additionally, the angular deviation between the two splined shafts should be less than ±0.05/25.4 mm.

● The spline bore of the coupling must be lubricated with lithium molybdenum disulfide grease or a similar grease.

● The coupling must undergo heat treatment to achieve a hardness of 29–45 HRC.

● The spline bore shall meet the Grade 1 accuracy specified in SAE-J498b (1971), with flat root and side-to-side tooth engagement. Flat key shaft.

● The keyways provided with T7, T67, and T6 series vane pumps are high-strength keys. Therefore, when installing or replacing the pump, it is essential to use these high-strength keys. If the keyway key needs to be replaced, the new key must have a hardness of 27–34 HRC. The corners of the key should be chamfered at an angle of 0.8–1 × 45° to avoid interference with the rounded corners inside the keyway. Drive shaft load.

● The installation requirements for a plain key shaft are the same as those specified for a splined shaft. In the design of this product series, the transmission shaft is intended solely for torque transmission; therefore, it must not be subjected to radial or axial loads.

Application Instructions

Hydraulic fluid

● Hydraulic Fluid Classification: HF-0, HF-2 – Anti-wear hydraulic oil

HF-1: Non-Anti-Wear Hydraulic Oil

HF-3: Oil-in-Water Emulsion

HF-4: Water-glycol hydraulic fluid

HF-5: Synthetic Hydraulic Fluid

● Recommended Hydraulic Fluid: It is recommended to use anti-wear hydraulic oil. All the maximum rated operating parameters and performance parameter values provided in this sample were obtained through tests conducted using this type of hydraulic fluid as the working medium.

● Other Hydraulic Fluids: When using hydraulic fluids other than anti-wear hydraulic oils, it is required to reduce the pump’s maximum rated operating parameters. In certain cases, it may also be necessary to increase the minimum suction-side filling pressure. For details, please refer to the relevant specialized sections.

● Oil viscosity—maximum viscosity (cold-start conditions, low speed, low pressure)……………………………860 cSt

Maximum viscosity (at full speed and high-pressure conditions) ………………………… 108 cSt

Optimal viscosity (longest service life) ……………………………30 cSt

Minimum viscosity (at full speed and high-pressure conditions, for HF-1, HF-3, HF-4, and HF-5 hydraulic fluids)… 18 cSt

Minimum viscosity (at full speed and high-pressure conditions, for HF-0 and HF-2 hydraulic fluids)……………10 cSt

● The viscosity index shall be at least 90 V.L. A higher viscosity index of the oil can broaden the operating temperature range, but may shorten the service life of the working fluid itself.

Application Instructions

Working fluid temperature: The working fluid temperature—whether high or low—primarily depends on viscosity and is also related to the material of the seals used. For standard seals, the temperature range is from -30℃ to 90℃.

Maximum working fluid temperature:

● HF-0, HF-1, HF-2 ……………………………… +100 ℃

● HF-3, HF-4……………………………………… +50 ℃

● HF-5……………………………………………… +70 ℃

● Biodegradable hydraulic fluid (organic ester and rapeseed oil-based fluid)… +100 ℃

Minimum working fluid temperature (which also depends on the maximum viscosity):

● HF-0, HF-1, HF-2, HF-5 ……………………… -18 ℃

● HF-3, HF-4……………………………………… +10 ℃

● Biodegradable hydraulic fluid (organic ester and rapeseed oil-based fluid)… -20 ℃

The relationship between operating temperature and viscosity: The determination of the operating temperature is related to the viscosity of the working fluid, the type of working fluid, and the characteristics of the hydraulic pump. Generally, the viscosity of the working fluid should be selected based on the optimal viscosity value required by the hydraulic pump at normal temperature. During cold starts, the hydraulic pump should operate under low-speed and low-pressure conditions until the working fluid's temperature rises and its viscosity reaches an acceptable level before it can run at full power.

Oil cleanliness requirements stipulate that the solid particle contamination level of the hydraulic fluid should not exceed Grade 8 according to NAS1618 (or ISO 18/14). Typically, filters with a filtration accuracy of 25 μm (or higher, with a β10 ≥ 100) can be used. The specifications of the suction strainer should meet the minimum required suction pressure. A recommended fine mesh density for the strainer is 100 mesh (149 μm). For systems requiring cold-start conditions or operating with fire-resistant hydraulic fluids, the size of the suction strainer should be increased or the strainer itself should be eliminated altogether.

Maximum allowable water content in the working fluid for water pollution of the working fluid:

Mineral oil-based fluid …………………………………………0.1%

Synthetic hydraulic fluids, crankcase oils, and biodegradable hydraulic fluids… 0.05%

If the moisture content is too high, the system should be dehydrated.

Installation connection dimensions

T6C single pump

T6CL single pump

Get Quote

Welcome to leave a message, there may be a discount

Note: Please leave your contact information and our professionals will contact you as soon as possible!