DP11 Series Vane Pumps with Middle and High Pressure

Key words:

Details

Specifications

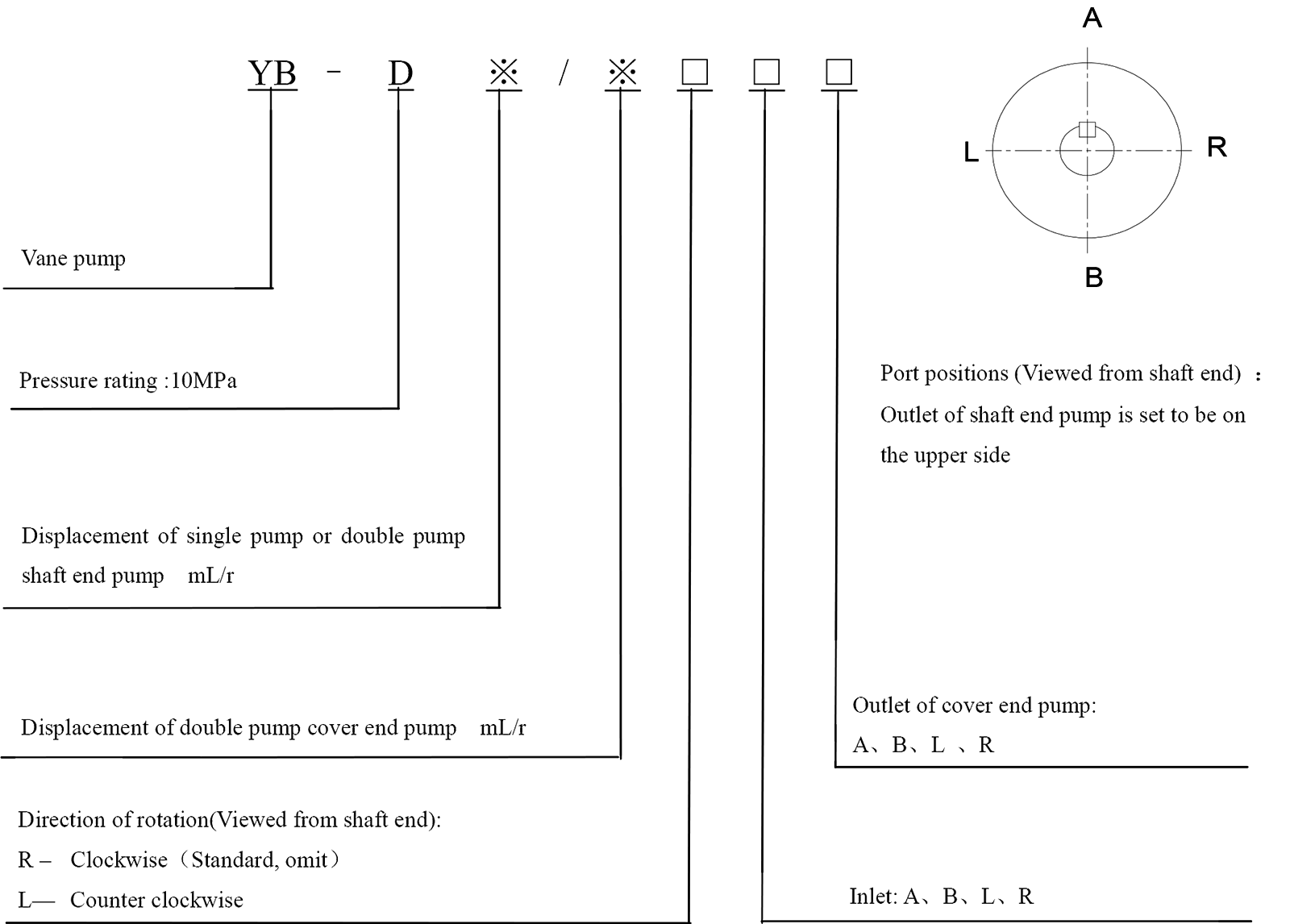

| Sub-series | Model |

| DP 11 | YB-D 4~10/4~10 |

Model Code

Installation and Use

1. In installation, the tolerance of concentricity between shaft of pump and motor must be less than 0.10mm (TIR) and the maximum permissible angle error is less than 0.2 degrees by using the flexible coupling; The pump shaft shall not bear the radial and axial load; The carrier must be firm with good rigidity and can fully absorb vibrations.

2.When installing, it is recommended that the suction inlet of the pump should be set up so that it is easy to absorb oil when it is started.

3. Fix pipes, especially inlet pipes in accordance with the size of port and assemble safety relief valves in the system; The regulating pressure of the safety valve shall not be greater than the maximum pressure of the pump; Inlet pipes must be strictly sealed with no leakage and the oil return nozzle should be below the fluid surface.

4.Check the inlet , outlet and direction of rotation before starting the pump. When operating the pump, newly fixed or not used for a long time, deflate it at the outlet. And as far as possible in the no-load condition of pump starting point mde (Preferably filled with oil in the pump).

5. When the pump is fixed above the oil surface of the tank, suction height should be lower than 500mm, with the inlet below the oil surface of the tank and the positive pressure of the inlet restricted within 0.03MPa.

6. Oil should be kept clean; pipes and tanks must be thoroughly cleared. Fix the sufficient-volume filter at the inlet of the pump 50mm above the bottom of the tank, with the suggested precision of 100μm. Precise filters should be assembled with the advised precision of 25μm in the system. The cleanness level of oil should be withinNAS12.

7. The working temperature of oil should be controlled between 15℃and 55C. If starting the pump in coldness, heat the oil, and after switching on the pump with no load, operate it continuously with no load.

8.Pay attention to the glue level and quality of the oil. Antiwear hydraulic oil, such as No.32, is recommended at lower temperature.

9. Turn the shaft of pump evenly and nimbly by hand after fixing the pump.

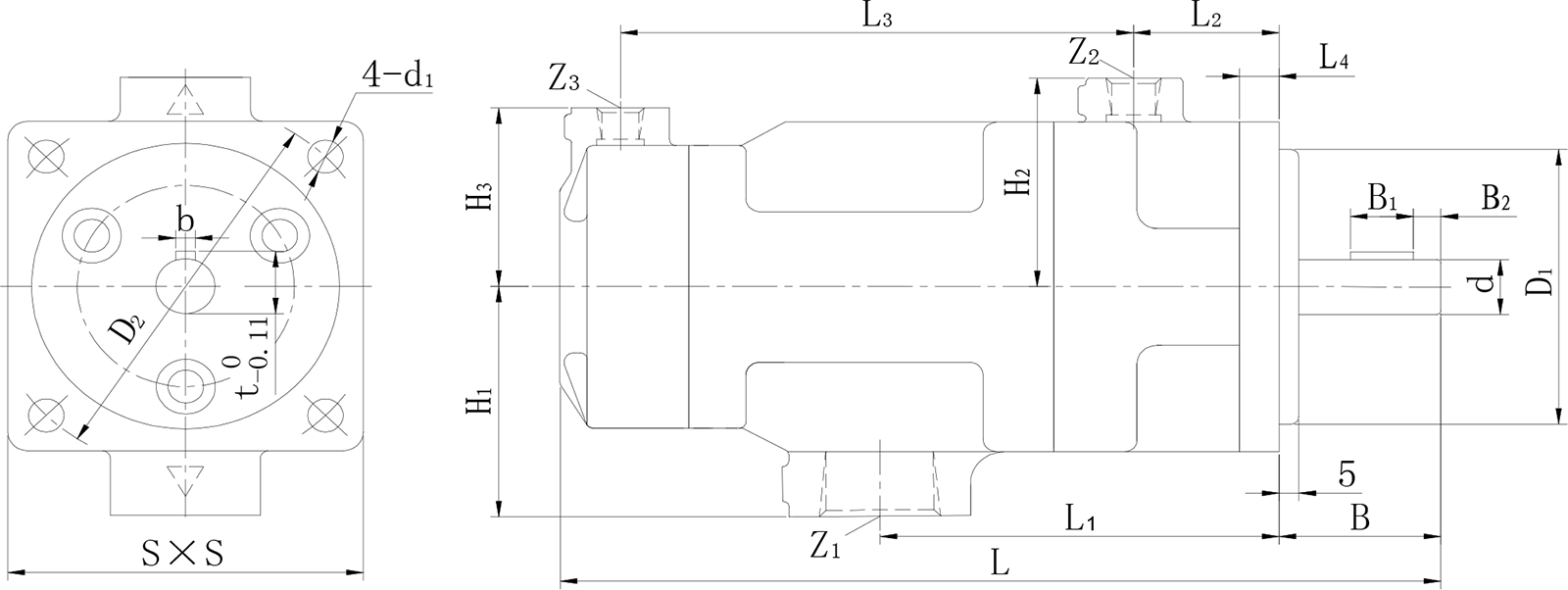

Install Connection Dimensions

| Subsidiary series | L | L1 | L2 | L3 | L4 | B | B1 | B2 | s | D1 | D2 | d | d1 | t | b | z1 | Z2 | Z3 | H1 | H2 | H3 | ||

| DP11 | 226 | 98.5 | 36 | 124 | 10 | 41 | 16 | 4 | 90 | φ75 | -0.03 -0.06 | φ100 | φ15 | 0 -0.011 | φ9 | 17 | 5 | NPT3/4 | NPT1/4 | NPT1/4 | 60 | 57 | 57 |

Get Quote

Welcome to leave a message, there may be a discount

Note: Please leave your contact information and our professionals will contact you as soon as possible!