10V Vane Pumps with High-Performance

Key words:

YB-E/VANE PUMP/HYDRAULIC PUMP

YB-E series vane pumps with high-performance are featured by advanced performance,reasonable structure, good creditability, lower noise, ultra-low pulse and stable quality.Precisely made, the products can be used in the equipment with high precision, and are widely used in cutting, plastic, forging and engineering machinery fields and so forth.

Details

Specifications

| Series | Model | Displacement mL/r | Speed r/min | Rated Pressure MPa | Input Power Kilowatt | Weight Kilogram |

| 10V | YB-E8 | 8.5 | 600-1800 | 16 | 4.5 | 8 |

| YB-E16 | 16.8 | 7.9 | ||||

| YB-E 25 | 24.4 | 11.7 | ||||

| YB-E 32 | 29.5 | 15.5 |

Note: 1. Input power is available in working conditions of 16MPa(50V, 10MPa) and 1500r/min.

2. Speed at 1000r/min is suggested on occasions with lower noise strictly required.

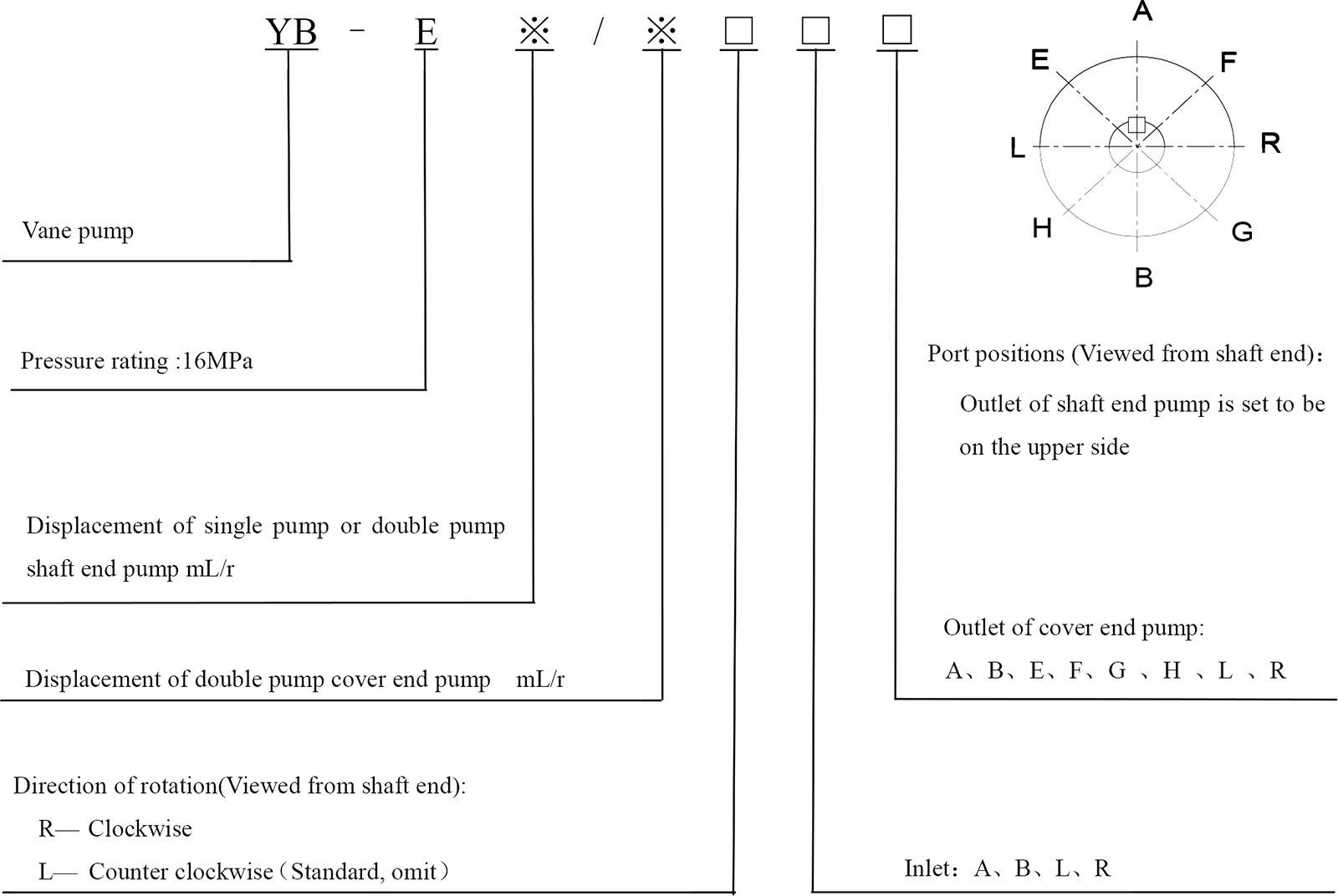

Model Code

Installation and Use

1. In installation, the tolerance of concentricity between shaft of pump and motor must be less than 0.10mm(TIR) and the maximum permissible angle error is less than 0.2 degrees by using the flexible coupling; The pump shaft shall not bear the radial and axial load; The carrier must be firm with good rigidity and can fully absorb vibrations.

2. If a pump is used at speed below 1200r/min, install the pump with the suction port upside so that the pump can suck up fluid easily at starting.

3.Fix pipes, especially inlet pipes in accordance with the size of port and assemble safety relief valves in the system; The regulating pressure of the safety valve shall not be greater than the maximum pressure of the pump; Inlet pipes must be strictly sealed with no leakage; The fuel tank shall be equipped with a diaphragm to separate the bubbles and dirt from the oil; The oil return nozzle should be lower the fluid surface, the minimum depth of 50mm, even in a low, too, when the permissible level of to avoid the formation of bubbles 0.

4. Oil should be kept clean, pipes and tanks must be thoroughly cleaned; Precise filters should be assembled with the advised precision of 25μm in the system, the cleanness level of oil should be withinNSA12.Fix the sufficient-volume filter (the rated flow rate should be greater than twice the pump flow) at the inlet of the pump 50mm above the bottom of the tank, with the suggested precision of 100pm(150 mesh).

5. Selection of hydraulic oil : This series pumps are applicable to various oil liquids, including petroleum series oil, Water-cut hydraulic fluid, synthetic hydraulic fluid etc.However, the specifications of the pumps such as maximum pressure and maximum pump speed may be changed according to the type of hydraulic fluids to be used. For details, please refer to the specifications of the pump concerned. To improve the pump performance, prolong service life, it is recommended to use anti-wear hydraulic oil (such as ISO VG32 or ISO VG46).When the oil viscosity 30 cSt is the best (to keep the temperature within 10 ~60℃ , the best is 35~50℃ ), especially to avoid high temperature continuous operation, otherwise the pump will shorten the service life, set the heater and cooler when necessary to adjust the oil temperature.

6. Check the inlet , outlet and direction of rotation before starting the pump. Turn the shaft of pump evenly and nimbly by hand after fixing the pump. It is best to fill the pump with oil for the first time. At an initial operation or at an operation after a long rest, the pump may have difficulty in sucking up fluid; In such cases, an air bleed valve should be installed beforehand on the discharge side or discharge air by slightly slackening the connection on the discharge side. At starting, operate the pump intermittently as far as possible with no load.

7. At startup, If the oil viscosity is higher than the suitable viscosity (46cSt), the pressure should be limited to50% or less of their respective rated values until the system has warmed up.

2. If a pump is used at speed below 1200r/min, install the pump with the suction port upside so that the pump can suck up fluid easily at starting.

3.Fix pipes, especially inlet pipes in accordance with the size of port and assemble safety relief valves in the system; The regulating pressure of the safety valve shall not be greater than the maximum pressure of the pump; Inlet pipes must be strictly sealed with no leakage; The fuel tank shall be equipped with a diaphragm to separate the bubbles and dirt from the oil; The oil return nozzle should be lower the fluid surface, the minimum depth of 50mm, even in a low, too, when the permissible level of to avoid the formation of bubbles 0.

4. Oil should be kept clean, pipes and tanks must be thoroughly cleaned; Precise filters should be assembled with the advised precision of 25μm in the system, the cleanness level of oil should be withinNSA12.Fix the sufficient-volume filter (the rated flow rate should be greater than twice the pump flow) at the inlet of the pump 50mm above the bottom of the tank, with the suggested precision of 100pm(150 mesh).

5. Selection of hydraulic oil : This series pumps are applicable to various oil liquids, including petroleum series oil, Water-cut hydraulic fluid, synthetic hydraulic fluid etc.However, the specifications of the pumps such as maximum pressure and maximum pump speed may be changed according to the type of hydraulic fluids to be used. For details, please refer to the specifications of the pump concerned. To improve the pump performance, prolong service life, it is recommended to use anti-wear hydraulic oil (such as ISO VG32 or ISO VG46).When the oil viscosity 30 cSt is the best (to keep the temperature within 10 ~60℃ , the best is 35~50℃ ), especially to avoid high temperature continuous operation, otherwise the pump will shorten the service life, set the heater and cooler when necessary to adjust the oil temperature.

6. Check the inlet , outlet and direction of rotation before starting the pump. Turn the shaft of pump evenly and nimbly by hand after fixing the pump. It is best to fill the pump with oil for the first time. At an initial operation or at an operation after a long rest, the pump may have difficulty in sucking up fluid; In such cases, an air bleed valve should be installed beforehand on the discharge side or discharge air by slightly slackening the connection on the discharge side. At starting, operate the pump intermittently as far as possible with no load.

7. At startup, If the oil viscosity is higher than the suitable viscosity (46cSt), the pressure should be limited to50% or less of their respective rated values until the system has warmed up.

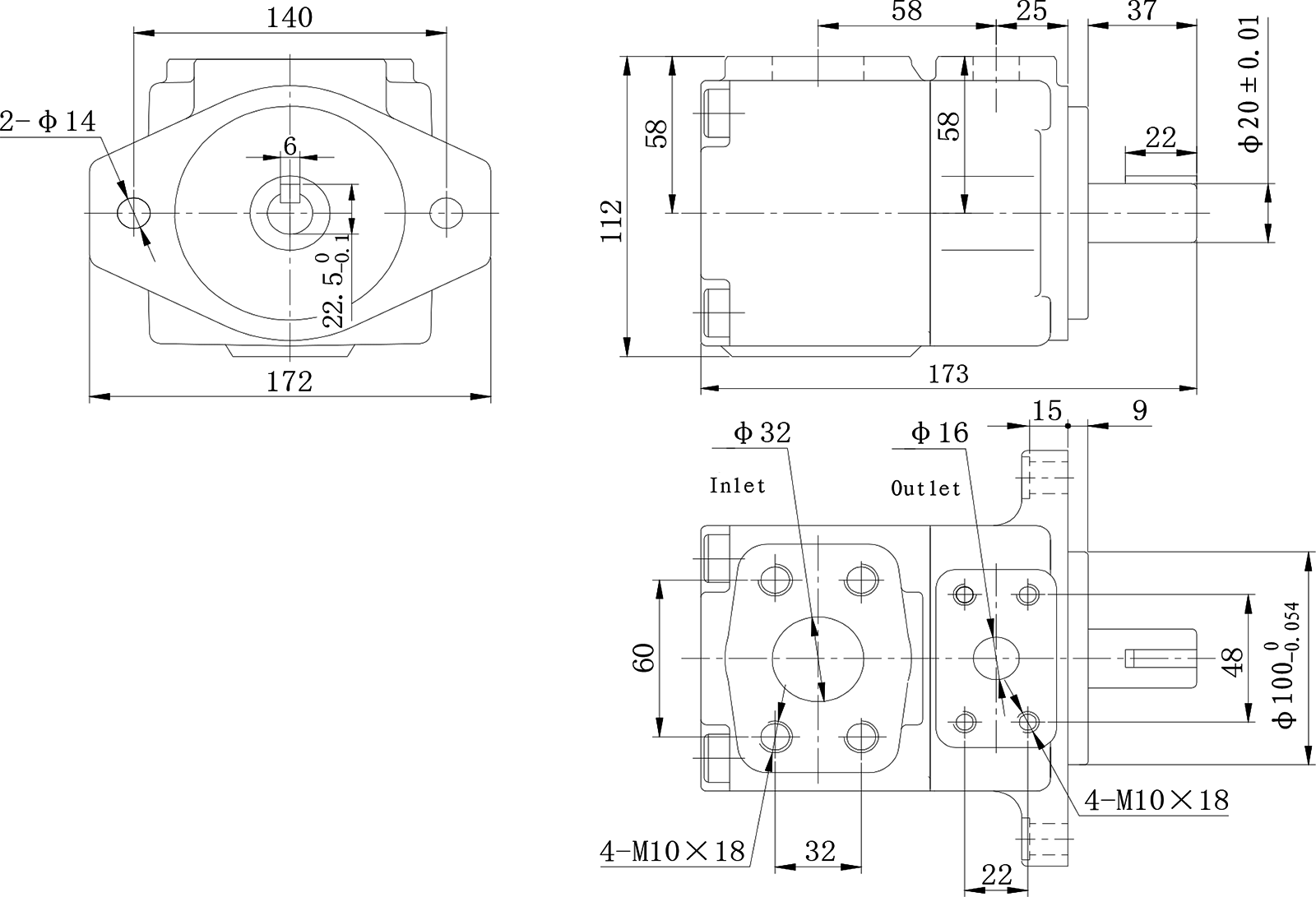

Install Connection Dimensions

Get Quote

Welcome to leave a message, there may be a discount

Note: Please leave your contact information and our professionals will contact you as soon as possible!