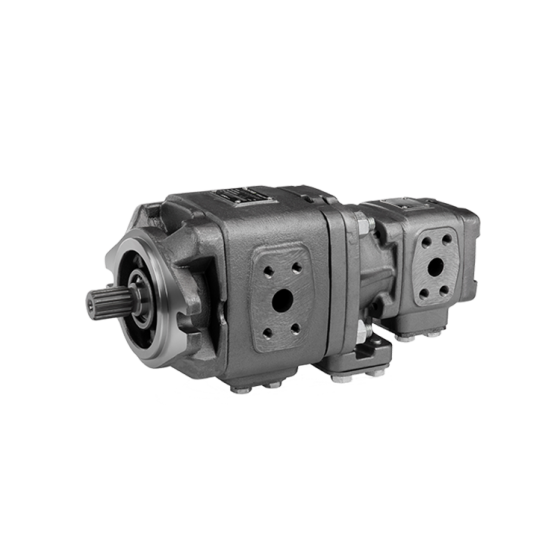

DP32 Medium- and High-Pressure Vane Pump

Key words:

Category:

Details

Technical Specifications

| Subseries code |

Model |

| DP 32 |

YB-D 31.5–50/12.5–25 |

Model Description

Installation and Use

1. During installation, the coaxiality error between the pump shaft and the drive motor shaft shall be less than 0.10 mm (as indicated by the total reading difference of a dial indicator). The maximum allowable angular error is less than 0.2°. A flexible coupling must be used, and the pump shaft must not bear any radial or axial loads. The support structure must be robust and highly rigid, capable of effectively absorbing vibrations.

2. During installation, it is recommended to position the pump’s suction port upward, so that oil can be easily drawn in when starting up.

3. Match the piping to the oil port dimensions, especially the inlet pipe, and install a safety relief valve in the system. The set pressure of the safety valve should not exceed the pump’s maximum operating pressure. The inlet piping must be tightly sealed to prevent air leakage, and the return oil pipe outlet should be positioned below the liquid level.

4. Before starting the pump, verify that the oil inlet and outlet ports and the rotation direction are correct. When starting a newly installed pump or a pump that has been idle for an extended period, bleed air from the oil outlet. Additionally, whenever possible, start the pump briefly in a no-load condition (preferably by filling the pump with oil first).

5. When the pump is installed higher than the oil level in the tank, the suction height should be ≤500 mm. Ideally, the suction port should be positioned below the oil level in the tank. The positive pressure at the suction inlet should be ≤0.03 MPa.

6. Keep the hydraulic fluid clean and ensure that the pipelines and oil tank are thoroughly cleaned. Install a filter with sufficient capacity at a position no less than 50 mm above the bottom of the oil tank, at the pump’s suction inlet (the filter’s rated flow rate should be more than twice the pump’s flow rate). A filtration accuracy of 100 μm (150 mesh) is recommended. A fine filter with a rating of 25 μm should also be installed in the system. The cleanliness level of the hydraulic fluid should be within NAS12 grade.

7. The operating temperature of the hydraulic oil should be maintained within the range of 15 to 55°C. When starting up in extremely cold conditions, the hydraulic oil should be warmed up. After briefly running the oil pump at no load several times, proceed with continuous operation at no load.

8. Pay attention to the viscosity and type of hydraulic oil. When the ambient temperature is low, we recommend using 32# anti-wear hydraulic oil.

9. After the entire pump has been installed, manually rotate the pump shaft; it should turn smoothly and freely.

Installation connection dimensions

| Subseries code |

L |

L1 |

L2 |

L3 |

L4 |

B |

B1 |

B2 |

S |

D1 |

D2 |

d |

d1 |

t |

b |

Z1 |

Z2 |

Z3 |

H1 |

H2 |

H3 |

||

| DP32 |

304 |

135 |

44 |

182 |

14 |

55 |

25 |

6 |

130 |

Φ90 |

-0.036 -0.071 |

Φ150 |

Φ25 |

0 -0.013 |

Φ14 |

28 |

8 |

NPT 1/1/4 |

NPT 1 |

NPT 3/4 |

90 |

85 |

72.5 |

Get Quote

Welcome to leave a message, there may be a discount

Note: Please leave your contact information and our professionals will contact you as soon as possible!