Products

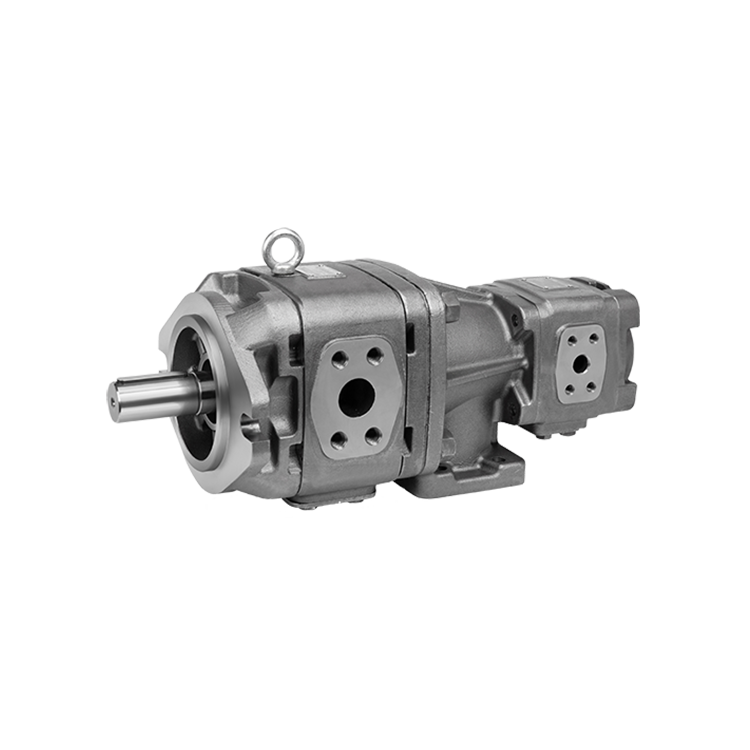

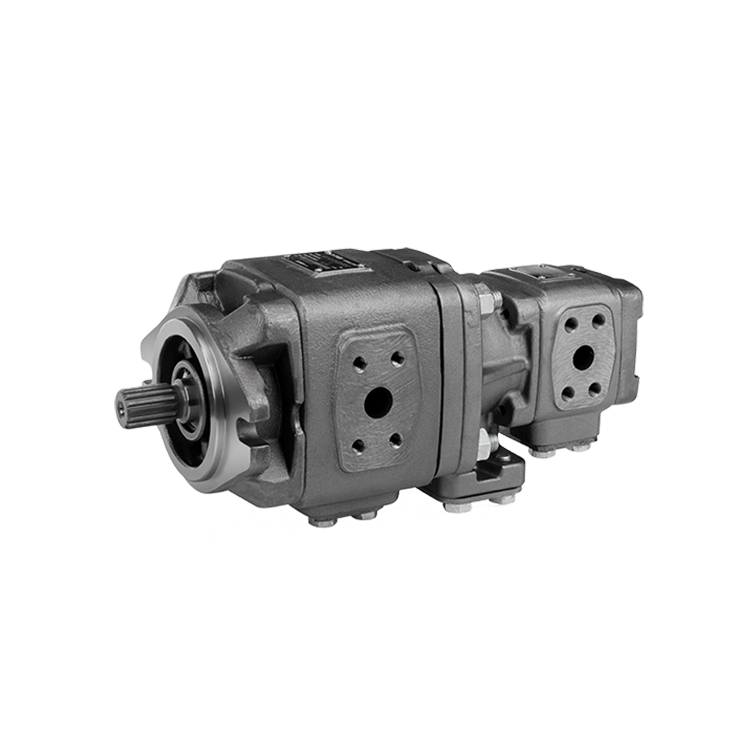

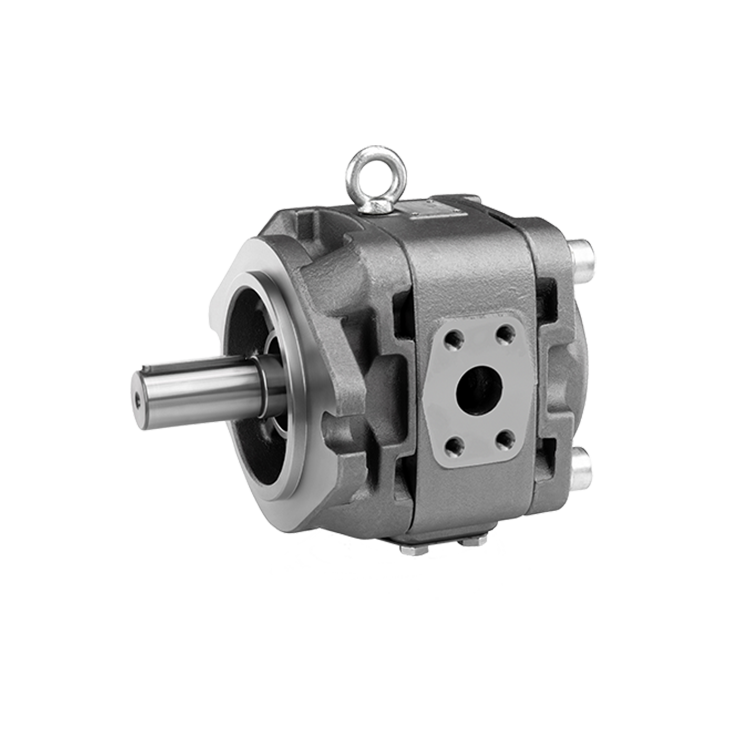

20VQ high-speed, high-pressure vane pump

Key words:Hydraulic tools

Details

Specification

| Model |

Displacement |

Geometry |

Anti-wear oil or |

Weight |

|

| Maximum Pressure |

Maximum Speed |

||||

| 20VQ |

2 |

7.5 |

14 |

2700 |

12 |

| 3 |

10.2 |

||||

| 4 |

12.8 |

||||

| 5 |

16.7 |

21 |

|||

| 6 |

19.2 |

||||

| 7 |

22.9 |

||||

| 8 |

26.2 |

||||

| 9 |

28.8 |

||||

| 10 |

31.0 |

||||

| 11 |

35.0 |

||||

| 12 |

37.9 |

16 |

|||

| 14 |

44.2 |

14 |

|||

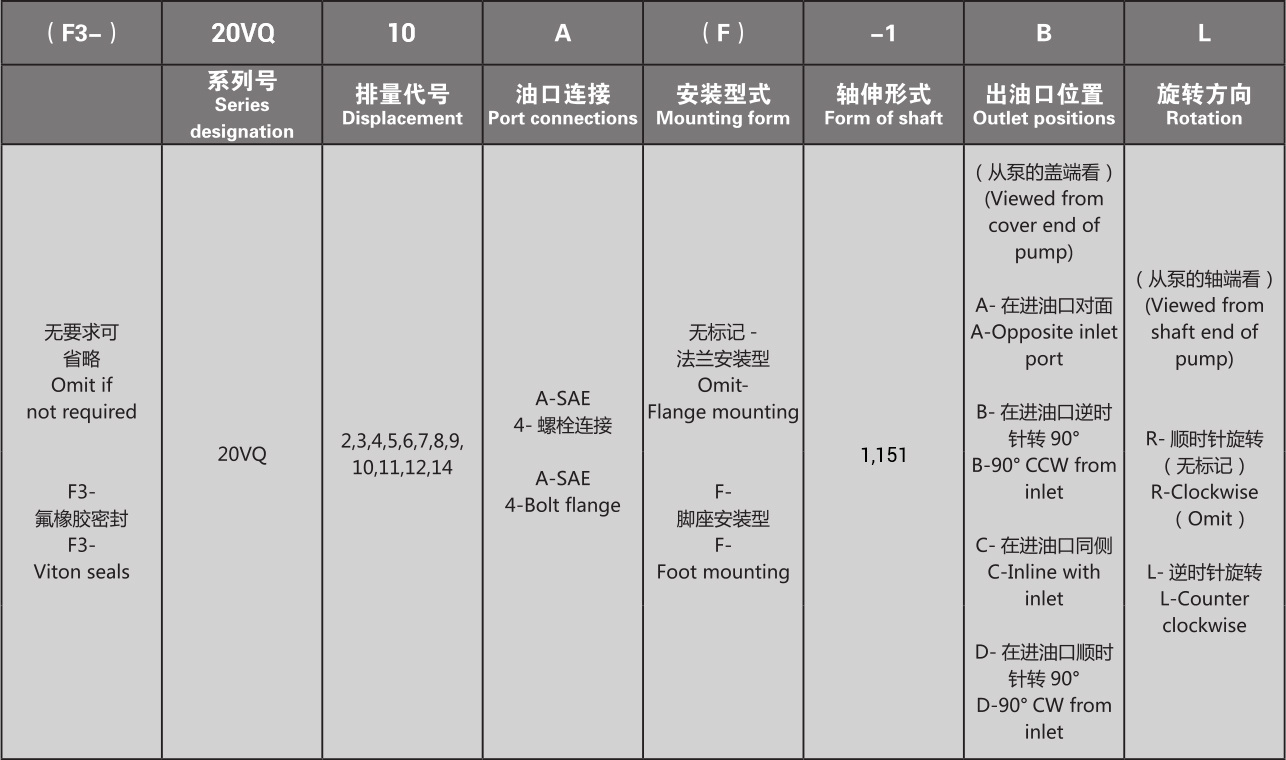

Model Code

Installation and Use

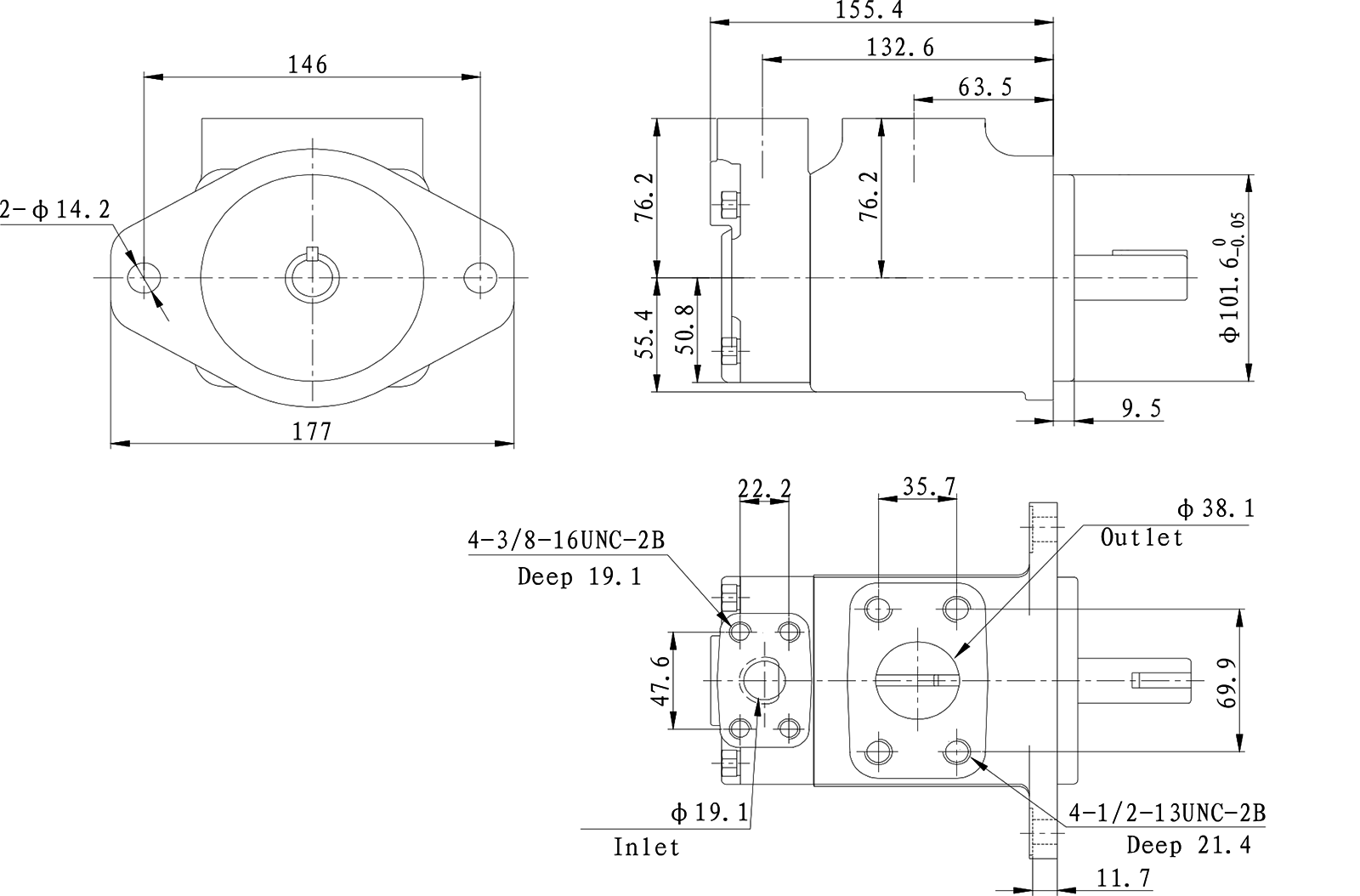

Installation Connection Dimensions

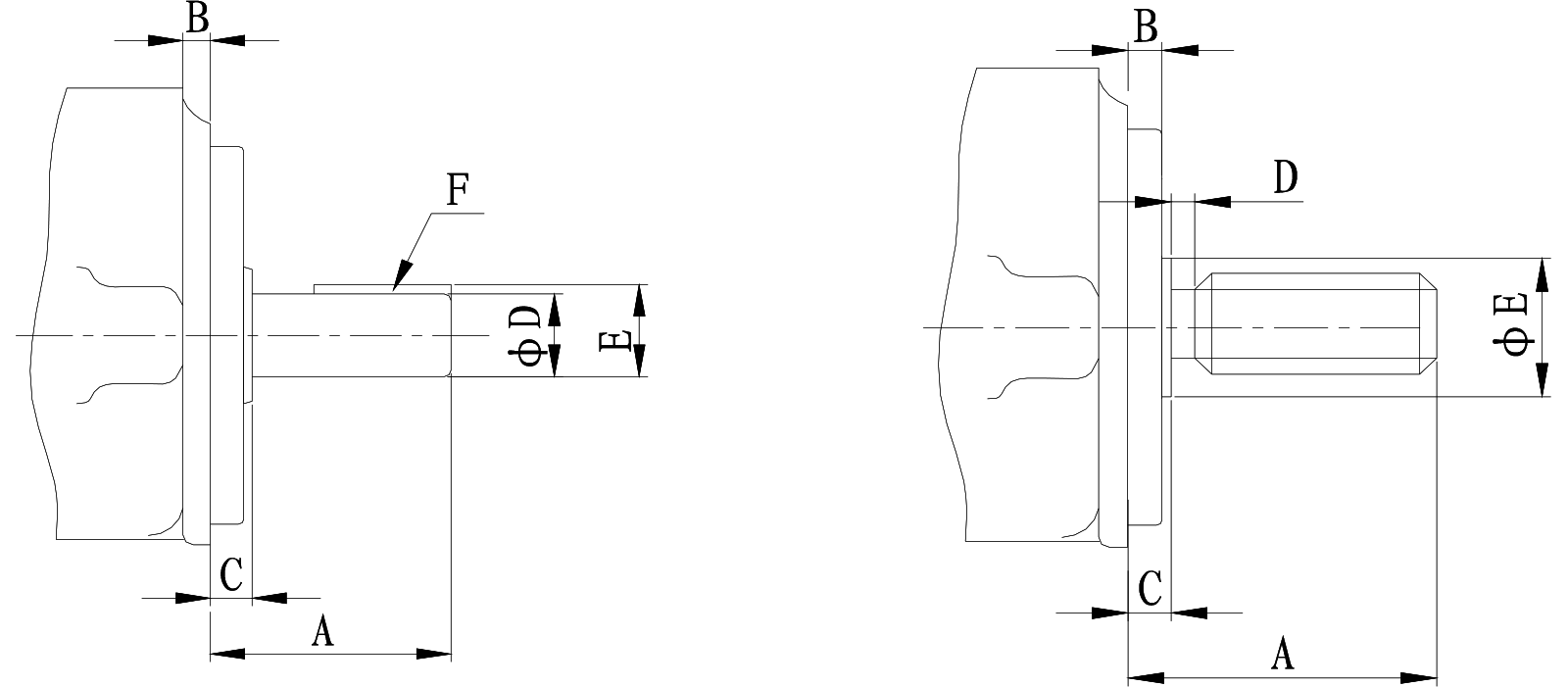

◎ Key Shaft

| Model |

Shaft Cooling |

A |

B |

C |

D |

E |

F Key |

| 20VQ |

1 |

59 |

9.5 |

12.0 |

22.225/22.20 |

24.5/24.35 |

4.75×32 |

◎ Splined Shaft

| Model |

Shaft Cooling |

A |

B | C |

D |

E |

Spline Data |

||||

| Number of Teeth |

Pitch |

Major Diameter |

Square Root |

Matching |

|||||||

| 20VQ |

151 |

41.1 |

9.5 |

11.1 |

3.9 |

27.8 |

13 |

22.17/22.15 |

18.63/18.35 |

Major Diameter Fit |

Large |

Get Quote

Welcome to leave a message, there may be a discount

Note: Please leave your contact information and our professionals will contact you as soon as possible!