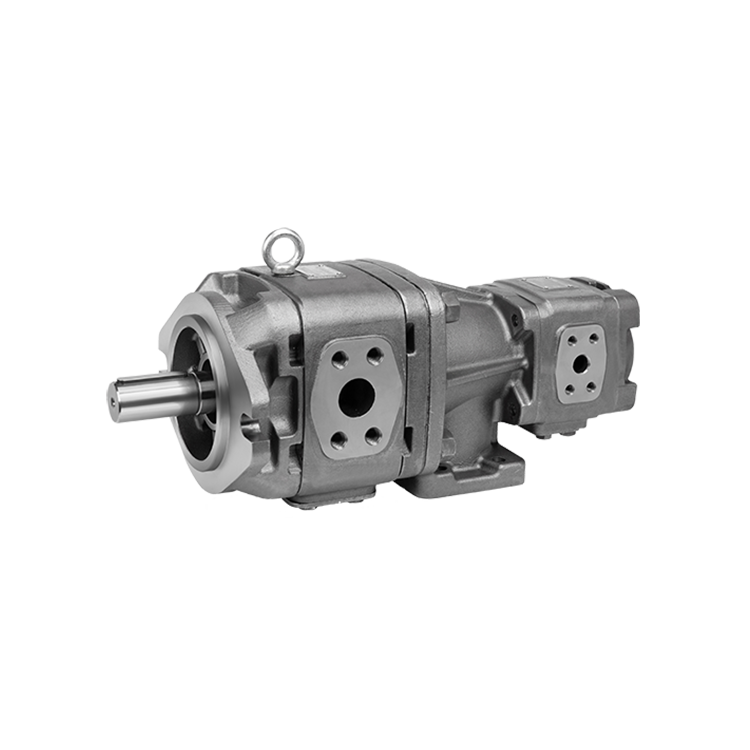

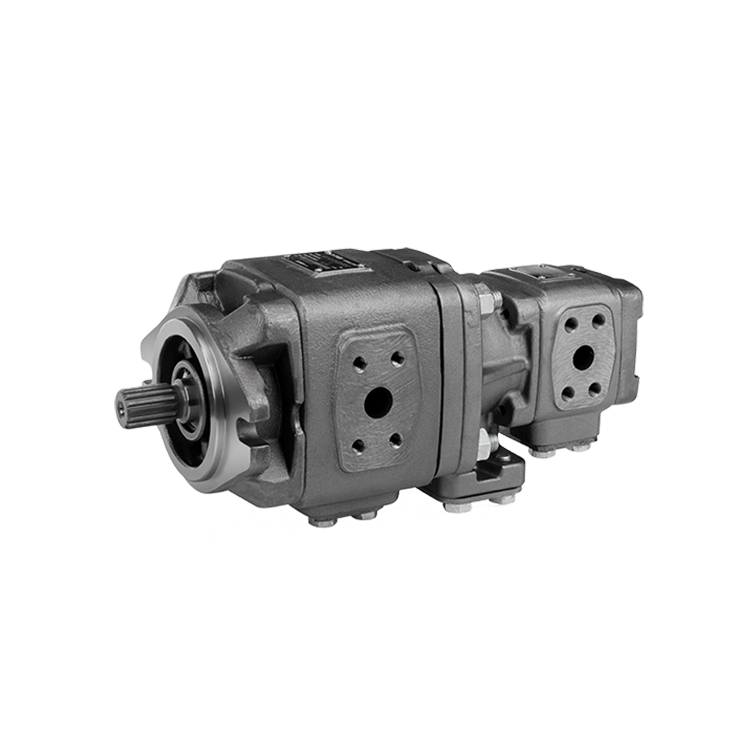

Products

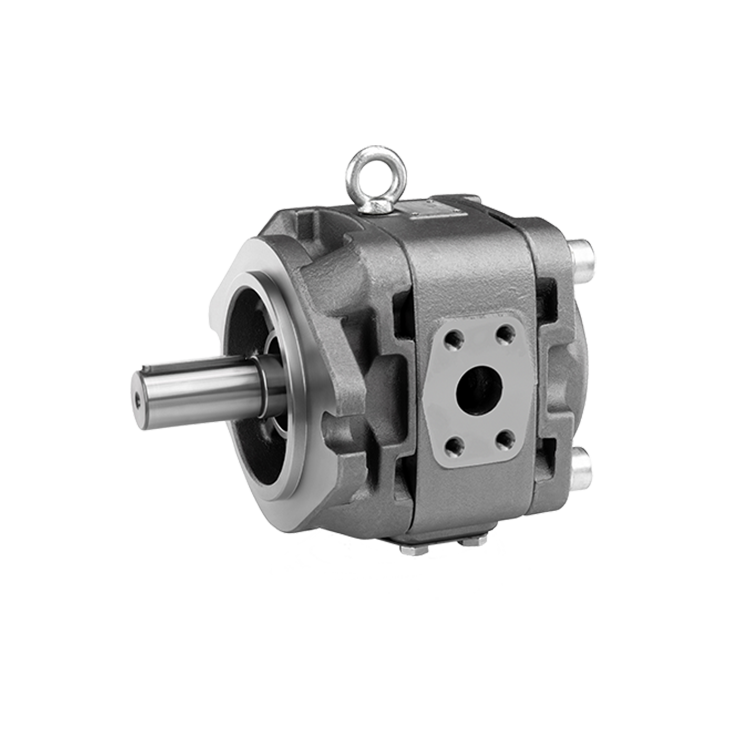

V20 vane pump

Key words:Hydraulic tools

Details

Specification

| Model | Displacement Code | Geometric Displacement mL/r | Anti-wear Oil or Phosphate Ester Liquid |

Water-Ethylene Glycol Liquid | Oil-in-Water Emulsion | |||

| Maximum Pressure MPa |

Maximum Speed r/min |

Maximum Pressure MPa |

Maximum Speed r/min |

Maximum Pressure MPa |

Maximum Speed r/min |

|||

| V20 | 6 | 19.5 | 17.2 | 3400 | 12.4 | 1800 | 10.9 | 1800 |

| 7 | 22.8 | 3000 | ||||||

| 8 | 26.5 | 2800 | ||||||

| 9 | 29.7 | |||||||

| 11 | 36.4 | 2500 | 10.9 | 9.3 | ||||

| 12 | 39 | 13 | 2400 | |||||

| 13 | 42.4 | |||||||

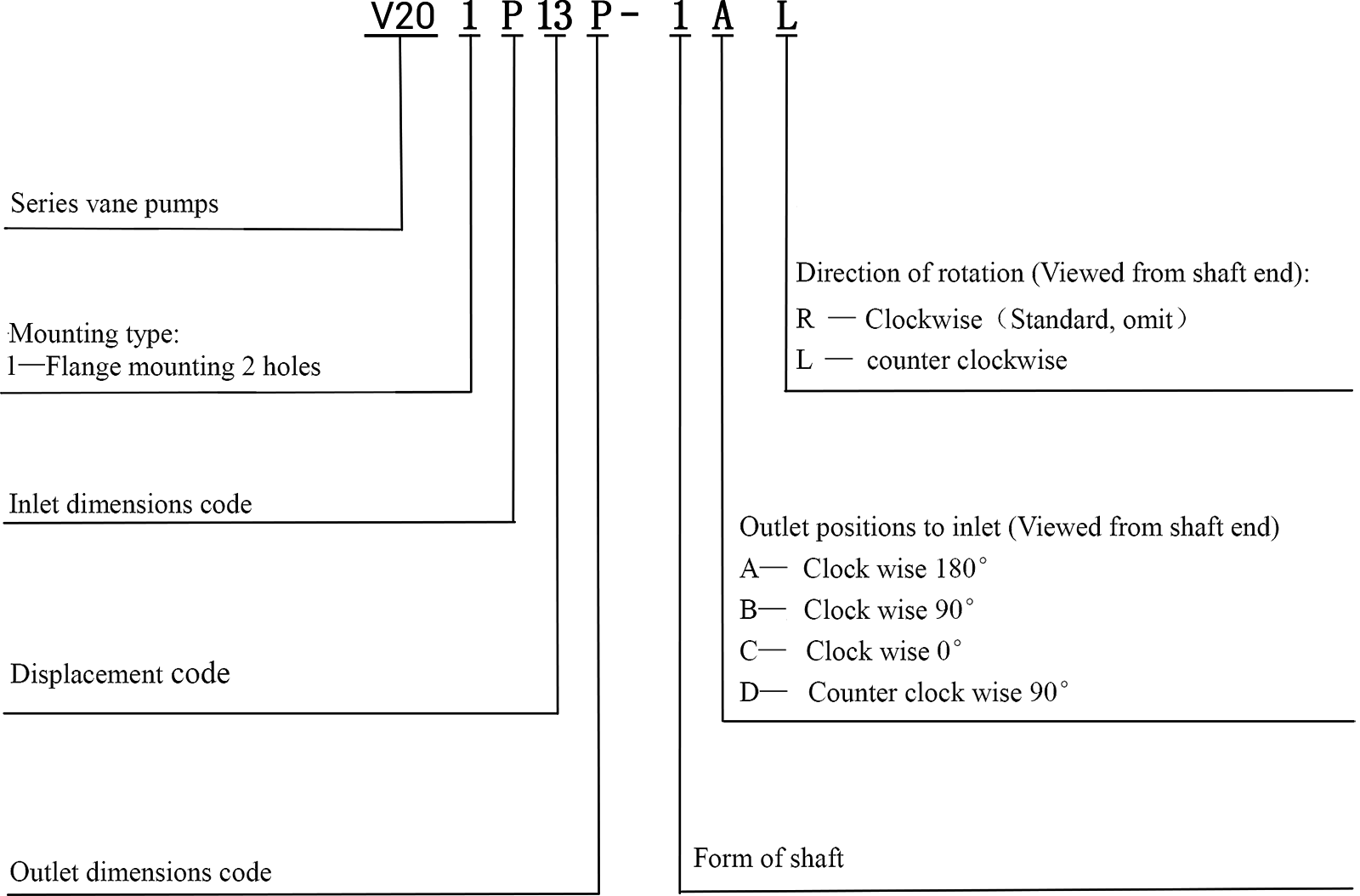

Model Code

Installation and Use

1. During installation, the concentricity tolerance between the pump and motor shafts must be less than 0.10 mm (TIR), the maximum allowable angular error must be less than 0.2 degrees, and a flexible coupling must be used; the pump shaft must not bear radial and axial loads; the bracket must be strong and rigid, and able to fully absorb vibrations.

2. Set the suction pressure of the pump inlet: The recommended inlet pressure is 0 to 35 Kpa.

3. The oil should be kept clean, and the pipelines and oil tank must be thoroughly cleaned; the cleanliness of the oil should be within NSA12.

4. Normal pump operation (under rated conditions) is based on using SAE10W oil (or equivalent viscosity) within the range of 38℃ to 82℃.

5. Check the inlet, outlet, and rotation direction before starting the pump. After fixing the pump, manually rotate the pump shaft evenly and flexibly. If the pump does not immediately pump water during the first start-up, air should be drained from the pump's delivery pipeline.

6. During the first use, the pump body and oil suction pipe should be filled with oil, and the pump must not run without oil.

7. Do not start the pump when the outlet pressure is lower than the inlet pressure. This will cause operational noise and blade instability.

8. Cold start conditions: When operating SAE10W oil in the range of 860 to 40 cSt, speed and pressure should be limited to 50% or less of their respective rated values until the system warms up. When the fluid viscosity is greater than 860 cSt, extreme caution must be exercised when starting the equipment, and attention should be paid to heating the entire system, including remote cylinders and motors.

9. At high temperatures, the viscosity must not be lower than 13 cSt, and the temperature must not exceed 99℃, because the expected life of the cartridge air bag and elastomer will be reduced.

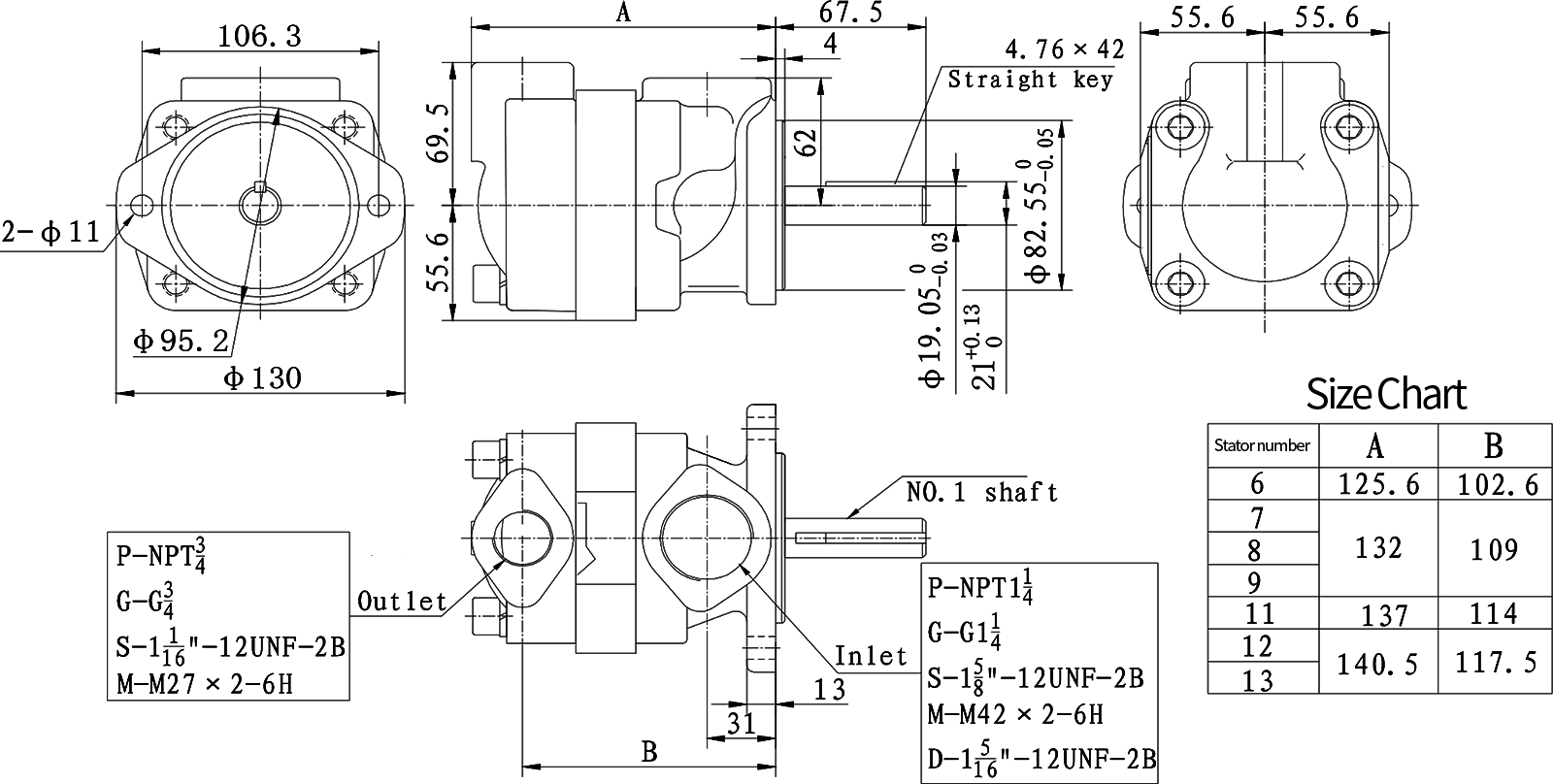

Installation Connection Dimensions

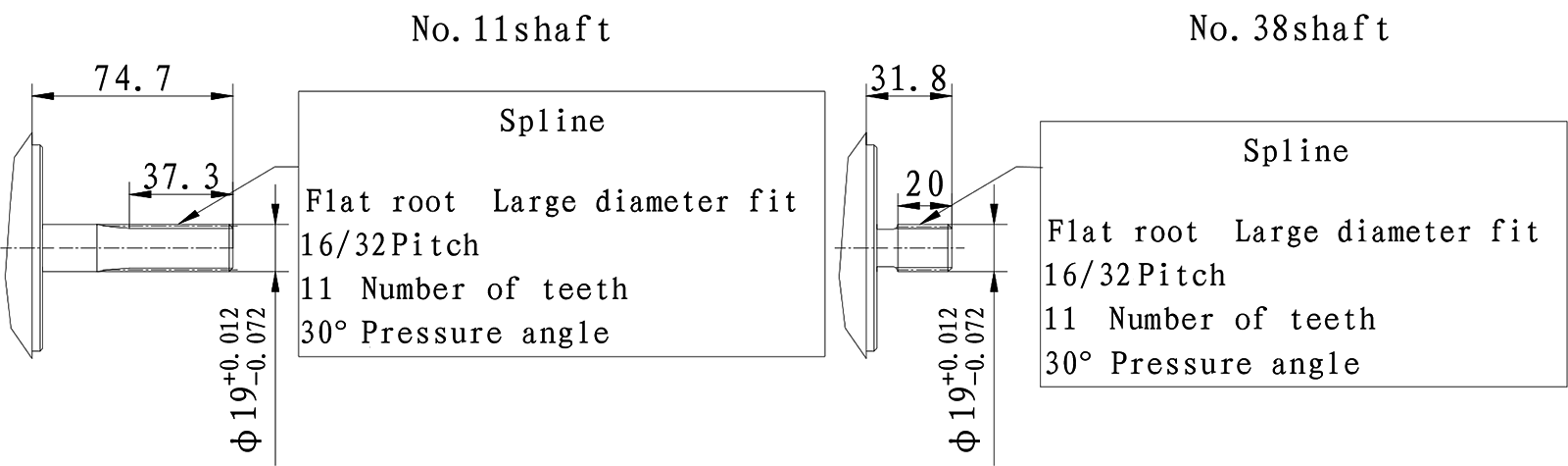

Shaft Form

Get Quote

Welcome to leave a message, there may be a discount

Note: Please leave your contact information and our professionals will contact you as soon as possible!