T6CC/T6CCL high-pressure needle valve pump

Key words:Hydraulic tools

Details

Specification

| Specification

|

PC

|

Displacement |

Minimum Speed |

Maximum Speed |

Maximum Pressure |

||||||

| HF-0 |

HF-3 |

HF-0, HF-2 |

HF-1, HF-4, HF-5 |

HF-3 |

|||||||

| Intermittent |

Continuous |

Intermittent |

Continuous |

Intermittent |

Continuous |

||||||

| mL/r |

r/min |

r/min |

r/min |

Bar |

Bar |

Bar |

Bar |

Bar |

Bar |

||

| T6CC T6CCL |

003 |

10.8 |

600 |

2200 |

1800 |

275 |

240 |

210

|

175

|

175

|

140

|

| 005 |

17.0 |

||||||||||

| 006 |

21.2 |

||||||||||

| 008 |

26.2 |

||||||||||

| 010 |

34.0 |

||||||||||

| 012 |

37.0 |

||||||||||

| 014 |

46.0 |

||||||||||

| 017 |

58.0 |

||||||||||

| 020 |

63.5 |

||||||||||

| 022 |

70.0 |

||||||||||

| 025 |

79.0 |

||||||||||

| 028 |

89.0 |

210 |

160 |

160 |

|||||||

| 031 |

100.0 |

||||||||||

Note: HF-0, HF-2 = Anti-wear Hydraulic Oil

HF-1 = General Hydraulic Oil

HF-3 = Oil-in-water emulsion

HF-4 = Water-glycerol fluid

HF-5 = Synthetic hydraulic fluid (phosphate esters, etc.)

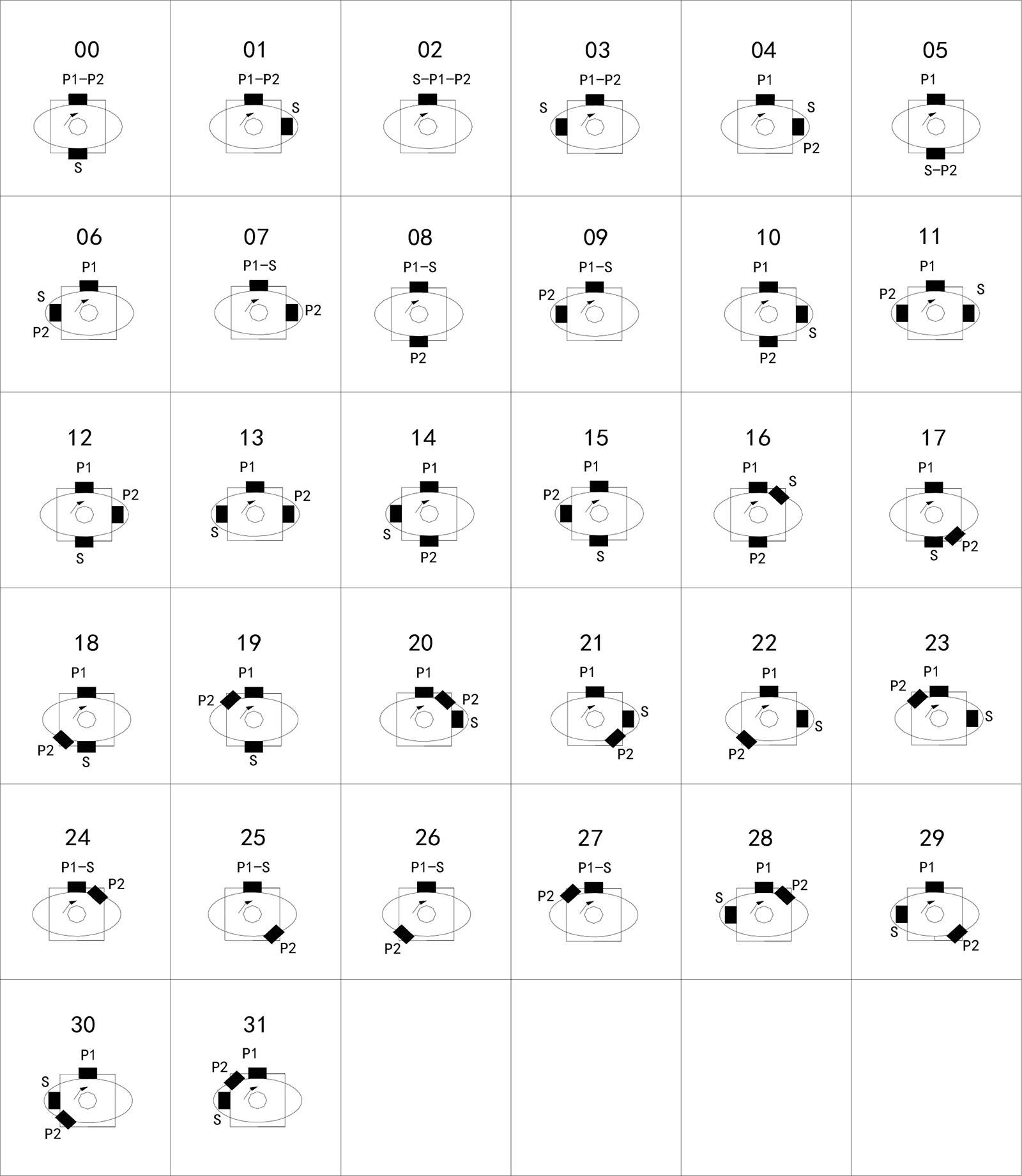

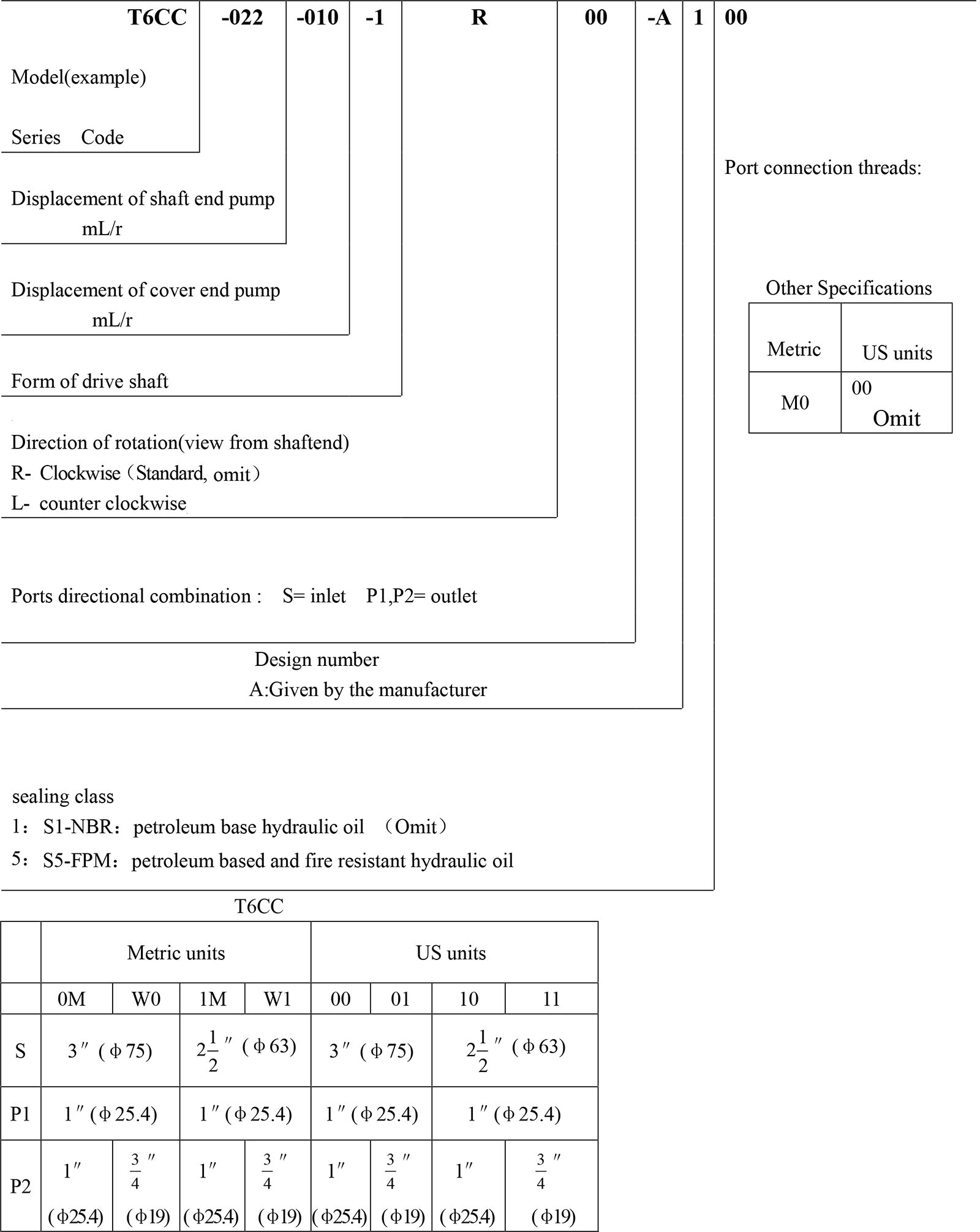

Model Code

Installation and Use

Initial Startup Check

Check the accuracy of the design and installation of the hydraulic station:

● Make the distance between the inlet and outlet as long as possible.

● The inlet and outlet pipe ports should have a slope, and the cross-sectional angle should be greater than or equal to 45° to increase the channel cross-section and reduce the speed. The recommended inlet water speed is between 0.5m/s and 1.9m/s, and the outlet water speed is below 6m/s.

● Confirm that the oil port is below the oil level in the oil tank (for example: all hydraulic cylinder pistons are extended to the limit position),

● The specification of the air filter should be more than three times the maximum reflux flow.

● Install a vent valve on the oil return pipe; you can also slightly loosen the joint at the pump outlet to vent until there are no air bubbles in the oil overflow, then you can tighten the joint to achieve the same effect.

Note: This method is suitable for low pressure, you should ensure that the pressure will not rise.

Initial startup:

● Check the accuracy of the oil port position.

● The pump should be well vented when adding oil.

● Run the pump for a few seconds for a short time, and the outlet safety valve should be loosened to achieve the minimum pressure.

● Do not drive the pump at high speed and high pressure before the inspection is completed.

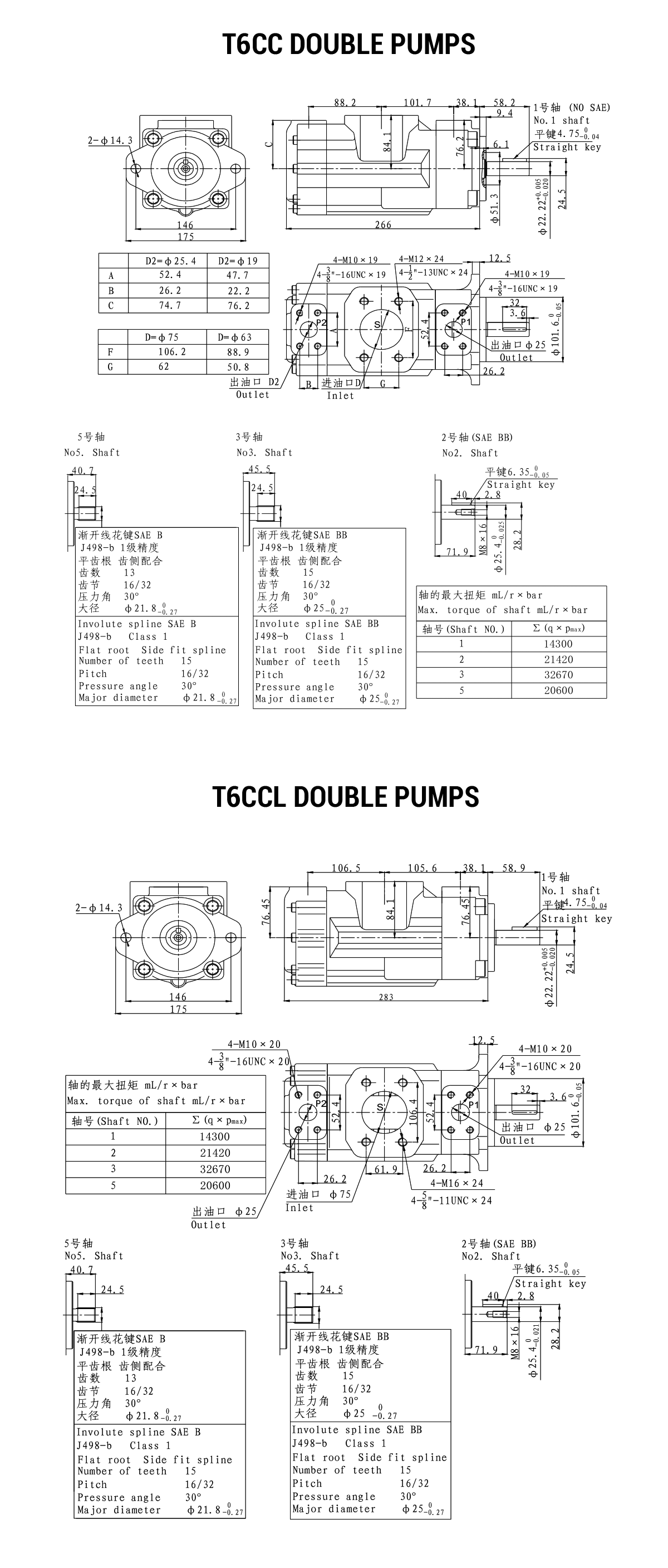

Shaft and Coupling

Coupling and spline bore

● The spline bore of the coupling should float and self-center to reduce wear, and the slope deviation of the two spline shafts should be less than or equal to ±0.05/25.4mm (indicator deviation)

● The spline bore must be lubricated with molybdenum disulfide lithium-based grease or other similar grease.

● The coupling requires heat treatment to achieve a hardness of 29~45HRC.

● The specification of the spline bore should comply with the Class 1 standard of SAE-J498b (1971), coordinated as flat root and side teeth.

Flat spline shaft

● T7, T67, and T6 series vane pumps provide high-strength keys, so they must be used when installing or replacing the pump, or a new key with a hardness of 27~34HRC and a chamfer angle of 0.8~1*45° can be used to avoid generating a fillet in the keyway when replacing the key.

Shaft Load

● The structure of the flat spline shaft requires the same as the spline shaft.

This series of products only allows transmission load and shall not apply radial and axial loads.

Hydraulic Oil

Hydraulic Oil Classification

HF-0, HF-2: Anti-wear hydraulic oil

HF-1: General hydraulic oil

HF-3: Oil-in-water emulsion

HF-4: Water-glycerol hydraulic oil

HF-5: Synthetic hydraulic oil

Recommended Hydraulic Oil

We recommend anti-wear hydraulic oil because all maximum rated operating parameters and performance parameters are based on tests using anti-wear hydraulic oil.

Other Hydraulic Oils

When using other hydraulic oils, you should reduce the maximum rated operating parameters of the pump. In some cases, you must increase the minimum pressure of the oil inlet. See the relevant chapter for details.

Viscosity

Maximum viscosity (cold start mode, low speed and low pressure)…………………………………860cSt

Maximum viscosity (full speed and high pressure)……………...……………..………………108cSt

Optimal viscosity (longest working time)…………………………………………………………30cSt

Minimum viscosity (full speed and high pressure, applicable to HF-1, HF-3, HF-4, HF-5)………18cSt

Minimum viscosity (full speed and high pressure, applicable to HF-0, HF-2)…………………………18cSt

Viscosity Index

Minimum index: 90V.L. High index can extend the operating temperature range, but may also shorten the service life of the working fluid.

Operating Temperature

The operating temperature mainly depends on the viscosity, and is also related to the sealing material. For standard seals, the range is -30 ℃ to 90 ℃.

Maximum Temperature

● HF-0, HF-1, HF-2….………………………………………………..………+100 ℃

● HF-3, HF-4.…………………………………………………………………..+50 ℃

● HF-5……………………………………………………………………………+70 ℃

● Biodegradable hydraulic oil (organic grease and rapeseed oil-based grease)…+100 ℃

Minimum liquid temperature (also depends on maximum viscosity)

● HF-0, HF-1, HF-2, HF-5………………………………………………….-18 ℃

● HF-3, HF-4……………………………………………………………………+10 ℃

● Biodegradable hydraulic oil (organic grease and rapeseed oil-based grease)…..-20 ℃

Operating temperature and viscosity

Operating temperature depends on viscosity, type of working fluid, and pump characteristics.

Generally, we use the most suitable viscosity. When the hydraulic pump cold starts, it should be driven under low speed and low pressure conditions to heat the liquid to the appropriate temperature, and then operate at full power.

Cleanliness of the working fluid

The solid contamination level of the oil is required to be below NAS1618 (or ISO 18/14) grade 8, and you can use a filter with a filtration accuracy of 25μm (or β 100 ≥100).

The solid contamination level should meet the minimum suction pressure requirements. The recommended filter mesh is 100 mesh (149μm). When the system needs cold start or uses fire-resistant oil, it is best to increase the filter size or remove the filter.

Water contamination of the working fluid

Mineral oil-based grease……………………………………………………...….0.1%

Synthetic hydraulic oil crankcase oil and biodegradable hydraulic oil….….0.05%

When the moisture content is too high, the system needs to be dehydrated.

Installation connection Size

Get Quote

Welcome to leave a message, there may be a discount

Note: Please leave your contact information and our professionals will contact you as soon as possible!