Products

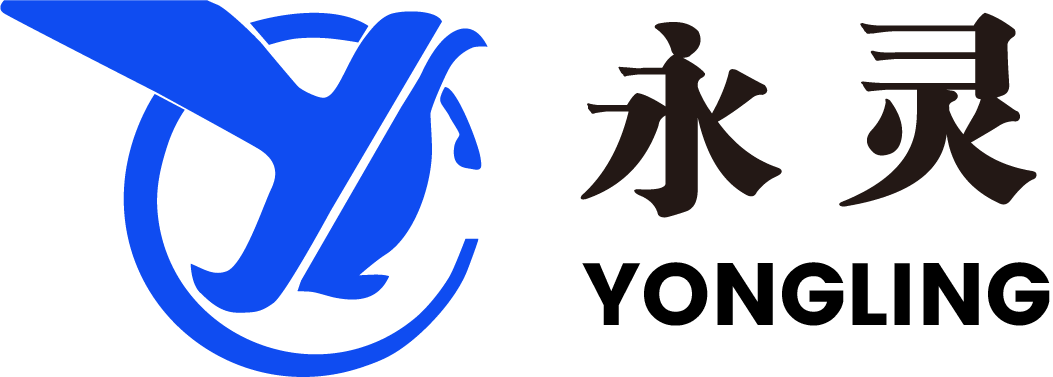

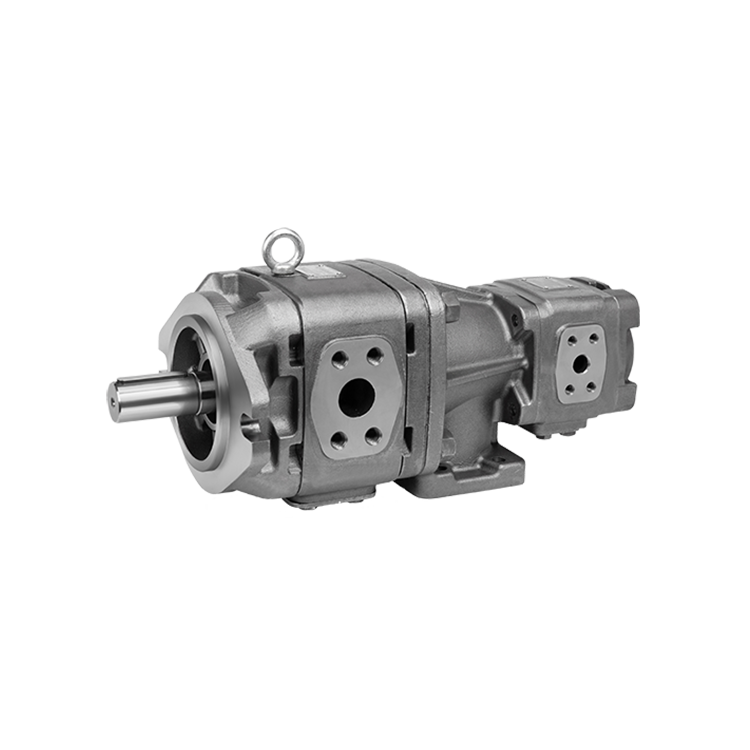

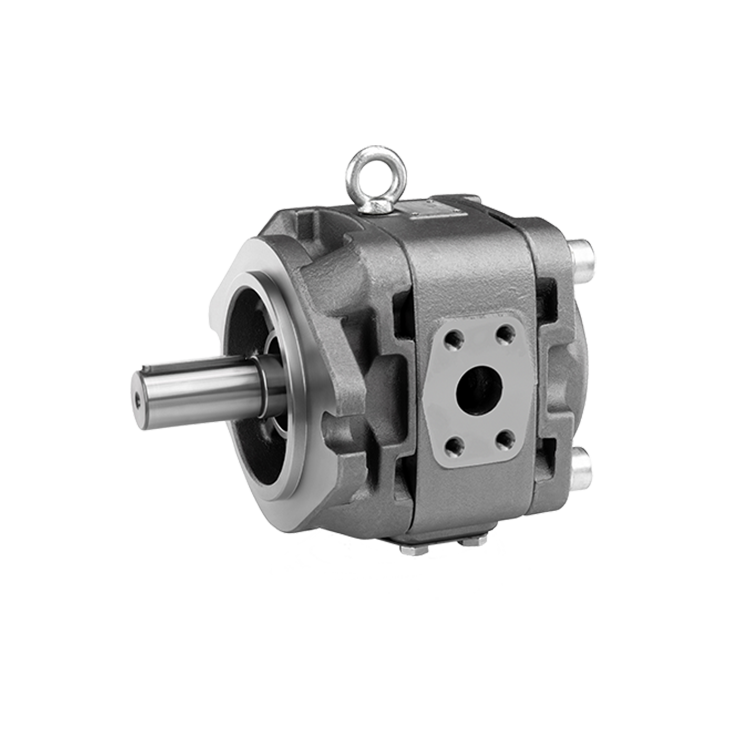

31V vane pump, high performance

Key words:Hydraulic tools

Details

Specification

| Series |

Axial piston pump displacement |

Gear pump displacement |

| 31V |

80, 100, 125 |

8, 16, 25, 32 |

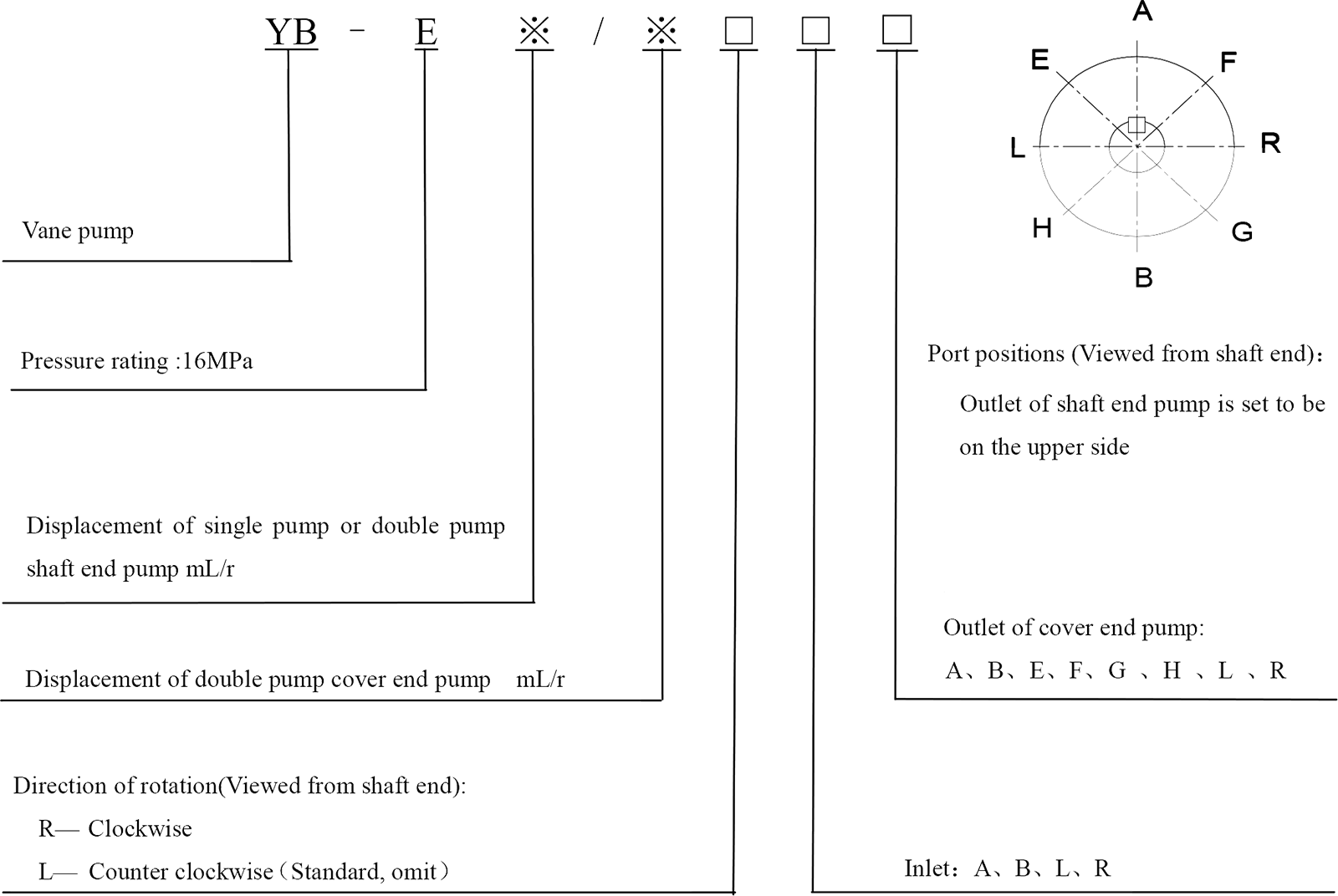

Model code

Installation and Use

1. During installation, the concentricity tolerance of the pump and motor must be less than 0.10 mm (TIR), and the maximum allowable angular error must be less than 0.2 degrees. When using a flexible coupling, the pump shaft must not bear radial and axial loads; the bracket must be strong and rigid, and able to fully absorb vibration.

2. During installation, it is recommended that the pump suction port should be set to facilitate oil suction during startup.

3. Secure the pipeline, especially the inlet pipe, according to the diameter size, and assemble a safety pressure relief valve in the system; the setting pressure of the safety valve must not exceed the maximum pressure of the pump; the inlet pipe must be strictly sealed to prevent oil leakage, and the return oil nozzle should be located below the liquid level.

4. Before starting the pump, check the inlet port, outlet port, and rotation direction. When operating the pump, if it is newly installed or has not been used for a long time, the air should be released from the outlet.

And start the pump as much as possible under no-load conditions (preferably with the pump full of oil).

5. When the pump is fixed above the oil surface of the oil tank, the suction height should be less than 500 mm, the inlet port should be located below the oil surface of the oil tank, and the positive pressure of the inlet port should be limited to within 0.03 MPa.

6. The oil should be kept clean; the pipeline and oil tank must be thoroughly cleaned. A filter with sufficient capacity is fixed 50 mm from the inlet port of the pump, and a precision of 100 μm is recommended. A precision filter with a precision of 25 μm should be assembled in the system. The cleanliness of the oil should be within NAS12.

7. The working temperature of the oil should be controlled between 15℃ and 55℃. If the pump is started in cold weather, the oil should be heated, and the pump should be turned on under no-load conditions and continue to run under no-load conditions.

8. Pay attention to the gum level and quality of the oil. It is recommended to use anti-wear hydraulic oil at low temperatures, such as No. 32 oil.

9. After fixing the pump, manually rotate the pump shaft evenly and flexibly.

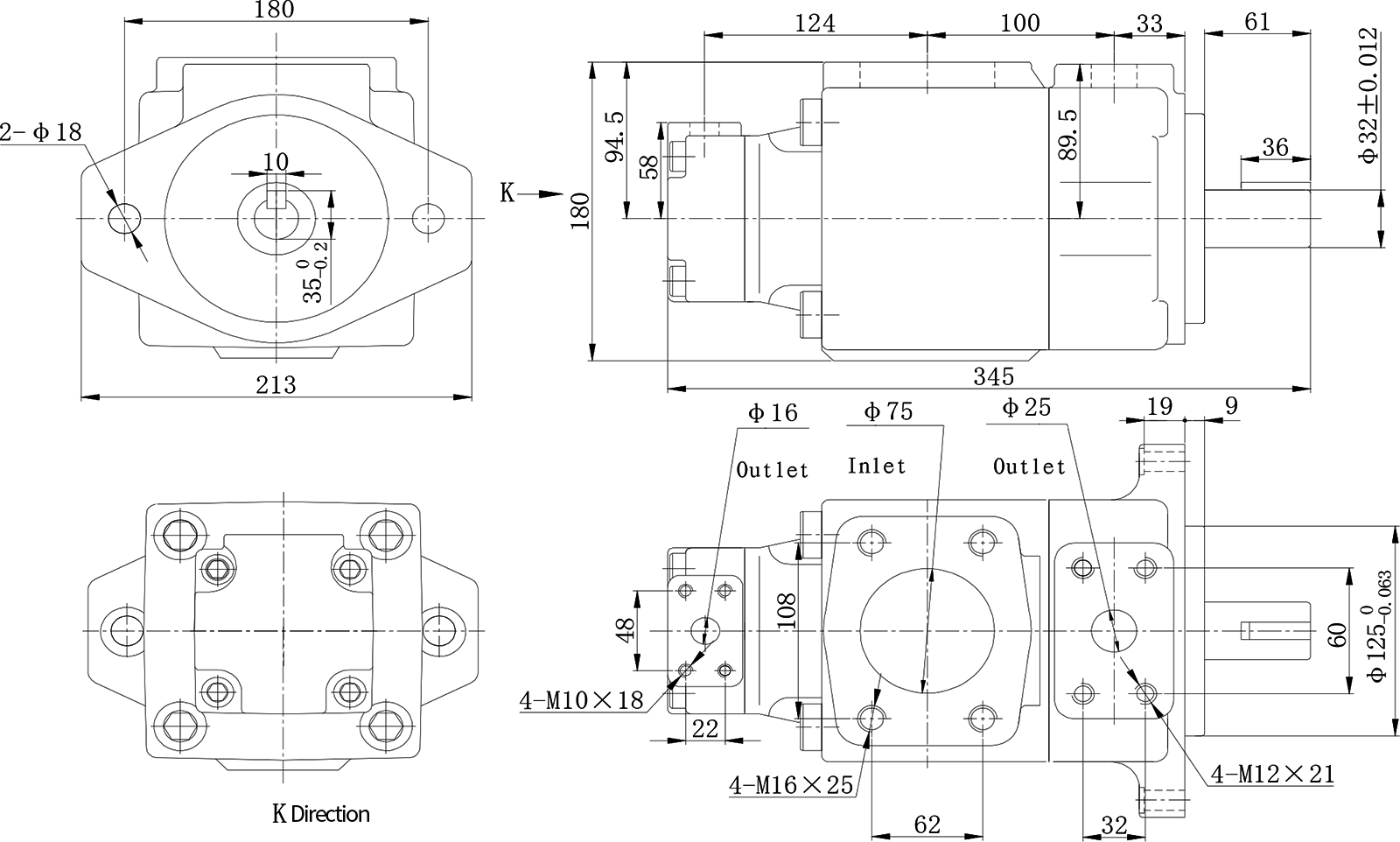

Installation connection Size

Install Connection Dimensions

Get Quote

Welcome to leave a message, there may be a discount

Note: Please leave your contact information and our professionals will contact you as soon as possible!