VP22 Variable Displacement Vane Pump

Key words:

VP/VANE PUMP/HYDRAULIC PUMP

VP Series variable Displacement vane pumps are the products with limiting pressure, equipped with both pressure and flow adjustment facilities. The outlet flow of the pump can regulate itself automatically according to the load, by which the outlet power and the working speed are in tune with the load. The pump is characterized by high efficiency, saving energy, safety and creditability and so on, and can be used in the hydraulic system for volumetric regulation, for instance, cutting machine tools, pressure and leather machinery, hydraulic station, and so on.

Details

Specifications

Model Code

Installation and Use

1. Clockwise rotation viewed from shaft end is standard.

2.The pump shaft must be horizontally installed. For proper alignment of pump and electric motor shaft,the eccentricity between them must be kept within 0.05mm and the eccentric angle error between them must be kept within 1 ". The shaft ends avoid increasing radial and axial loads. In addition, please use sufficient rigid material as the mounting bracket.

3. Fix pipes, especially inlet pipes, in accordance with the size of port ;

2.The pump shaft must be horizontally installed. For proper alignment of pump and electric motor shaft,the eccentricity between them must be kept within 0.05mm and the eccentric angle error between them must be kept within 1 ". The shaft ends avoid increasing radial and axial loads. In addition, please use sufficient rigid material as the mounting bracket.

3. Fix pipes, especially inlet pipes, in accordance with the size of port ;

Inlet pipes must be strictly sealed with no leakage;

System should be equipped with cooling device (without cooling unit, should increase fuel tank volume);

The fuel tank shall be equipped with a diaphragm to separate the bubbles and dirt from the oil;

The oil return nozzle should be lower the fluid surface, the minimum depth of 50mm, even in a low, too, when the permissible level of to avoid the formation of bubbles;

Inlet port pressure should be -0.03 to +0.03MPa; In case where the pump is installed on the tank or at the position higher than the tank top cover,the height of the suction port of the pump should be less than500mm,

4.Drain connection must be piped directly to tank and below the oil level with a back pressure not exceed 0.03MPa.

5, The setting value of P-Q at the factory:

System should be equipped with cooling device (without cooling unit, should increase fuel tank volume);

The fuel tank shall be equipped with a diaphragm to separate the bubbles and dirt from the oil;

The oil return nozzle should be lower the fluid surface, the minimum depth of 50mm, even in a low, too, when the permissible level of to avoid the formation of bubbles;

Inlet port pressure should be -0.03 to +0.03MPa; In case where the pump is installed on the tank or at the position higher than the tank top cover,the height of the suction port of the pump should be less than500mm,

4.Drain connection must be piped directly to tank and below the oil level with a back pressure not exceed 0.03MPa.

5, The setting value of P-Q at the factory:

Flow setting : The max. flow as catalogue shown.

Pressure setting : The min. operating pressure range.

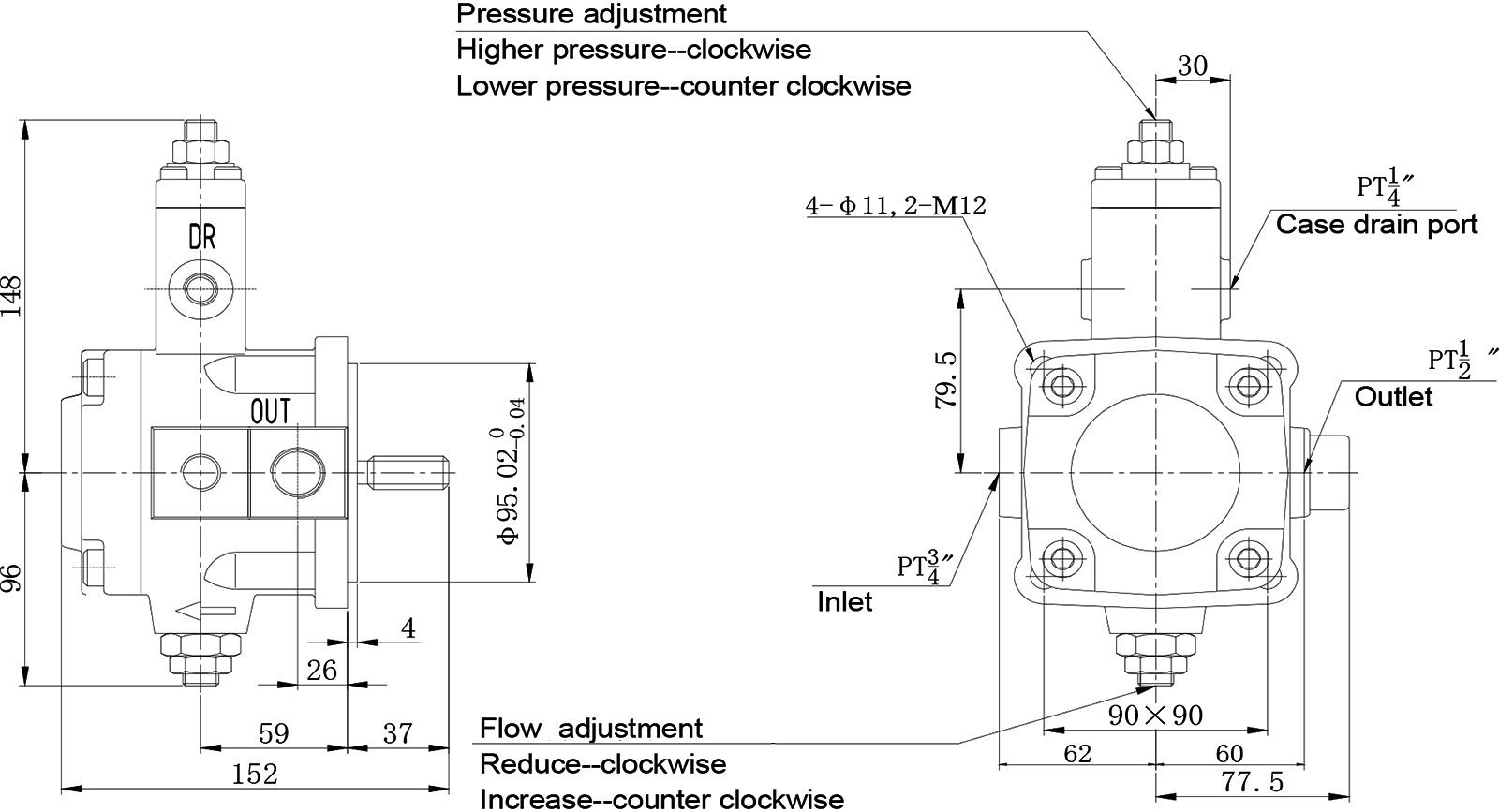

6. Flow and pressure adjustment:

For adjusting them, first loosen the tightly locked nut, and then spin screws, After adjustment, tighten the lock nut.

The flow will be reduced when the flow adjusting screw is turned clockwise and increased when anti-clockwise.

The pressure will be increased when the pressure adjusting screw is turned clockwise and reduced when anti-clockwise.

7.Thrust bolt:

The thrust bolts are set when the pump is assembled , Please do not adjust,

8. Hydraulic oil:

Use the hydraulic oil of 30 ~ 50cSt (ISO VG32) at 40℃. The hydraulic oil temperature range of 15 ~60 ℃. Initial oil temperature below 15℃, please use the low voltage operation to oil temperature15C.

9. Oil should be kept clean, pipes and tanks must be thoroughly cleaned.

Precise filters should be assembled with the advised precision of 25μm in the system, the cleanness level of oil should be within NSA10;Fix the sufficient-volume filter (the rated flow rate should be greater than twice the pump flow )at the inlet of the pump 50mm above the bottom of the tank, with the suggested precision of 100pm(150 mesh).

10.To ensure adequate lubrication of the pump sliding surface, please fill the pump body before running.

11. First use :Start up the pump under No-Load condition and repeat to start and stop the motor several times to extract the air from inside of the pump and piping. Then keep a 10 minutes continuous running for a better de-airing. For exhaust pipes, install an exhaust valve.

For adjusting them, first loosen the tightly locked nut, and then spin screws, After adjustment, tighten the lock nut.

The flow will be reduced when the flow adjusting screw is turned clockwise and increased when anti-clockwise.

The pressure will be increased when the pressure adjusting screw is turned clockwise and reduced when anti-clockwise.

7.Thrust bolt:

The thrust bolts are set when the pump is assembled , Please do not adjust,

8. Hydraulic oil:

Use the hydraulic oil of 30 ~ 50cSt (ISO VG32) at 40℃. The hydraulic oil temperature range of 15 ~60 ℃. Initial oil temperature below 15℃, please use the low voltage operation to oil temperature15C.

9. Oil should be kept clean, pipes and tanks must be thoroughly cleaned.

Precise filters should be assembled with the advised precision of 25μm in the system, the cleanness level of oil should be within NSA10;Fix the sufficient-volume filter (the rated flow rate should be greater than twice the pump flow )at the inlet of the pump 50mm above the bottom of the tank, with the suggested precision of 100pm(150 mesh).

10.To ensure adequate lubrication of the pump sliding surface, please fill the pump body before running.

11. First use :Start up the pump under No-Load condition and repeat to start and stop the motor several times to extract the air from inside of the pump and piping. Then keep a 10 minutes continuous running for a better de-airing. For exhaust pipes, install an exhaust valve.

Installation Connection Dimension

Str. Key shaft

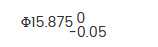

Spline shaft

According to American ANSI B92.1 specifications, accuracy grade: Grade 5

| Module | D.P.16/32 |

| Pressure Angle | 30° |

| Number of Teeth | 9 |

| Pitch Diameter | Φ14.2875 |

| Maximum Diameter |  |

| Minimum Diameter | Φ11.811(MAX) |

Get Quote

Welcome to leave a message, there may be a discount

Note: Please leave your contact information and our professionals will contact you as soon as possible!